Sustainable and flexible automation for vertical farming

Reducing costs, increasing scalability and promoting sustainability

The vertical farming industry is currently a 3 billion USD industry. However, many operations are still only able to profitably grow a limited number of crops, including leafy greens, herbs and smaller vegetables.

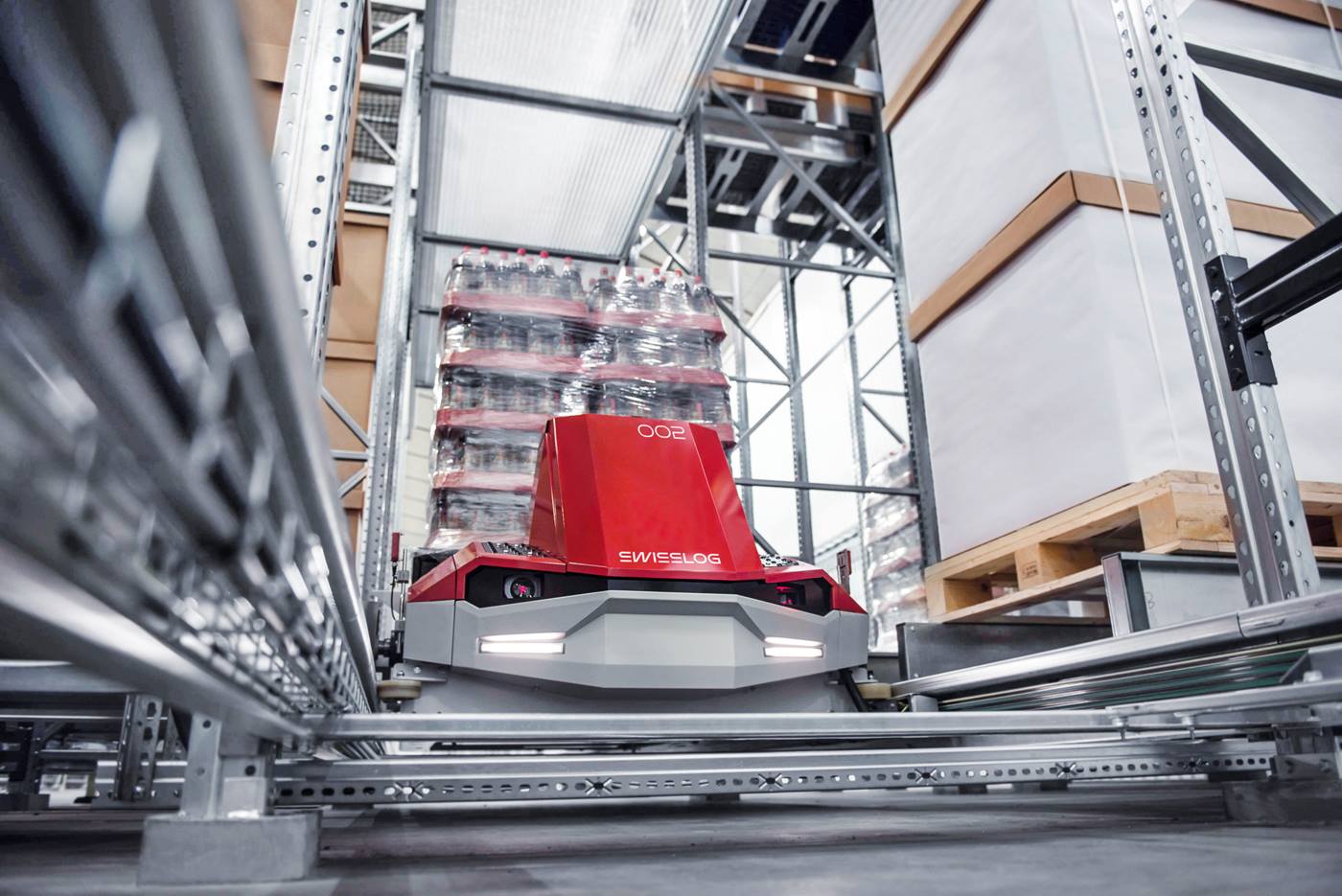

By applying a logistics-market approach to vertical farming, Swisslog provides sustainable and flexible automation solutions to help vertical farming become profitable and scalable beyond the niche applications it currently occupies.

The broad portfolio of Swisslog automation solutions provides enormous flexibility in customizing systems and configurations based on the strategy, growing process, crop type and space availability of the vertical farming operation.

For instance, using a shuttle system to move around discrete plant shelving units holding multiple plant trays based on the needs of the plants for water, nutrients, light, planting, germination, monitoring, maintenance and harvesting.

A modular solution making a sustainable difference

Vertical farming can produce more food from less land and water than traditional farming methods. It also drastically reduces chemical fertilizer and pesticide usage.

Bringing supply chain automation to vertical farming helps lower the environmental impact of growing organic, fresh produce and delivers measurable sustainability benefits.

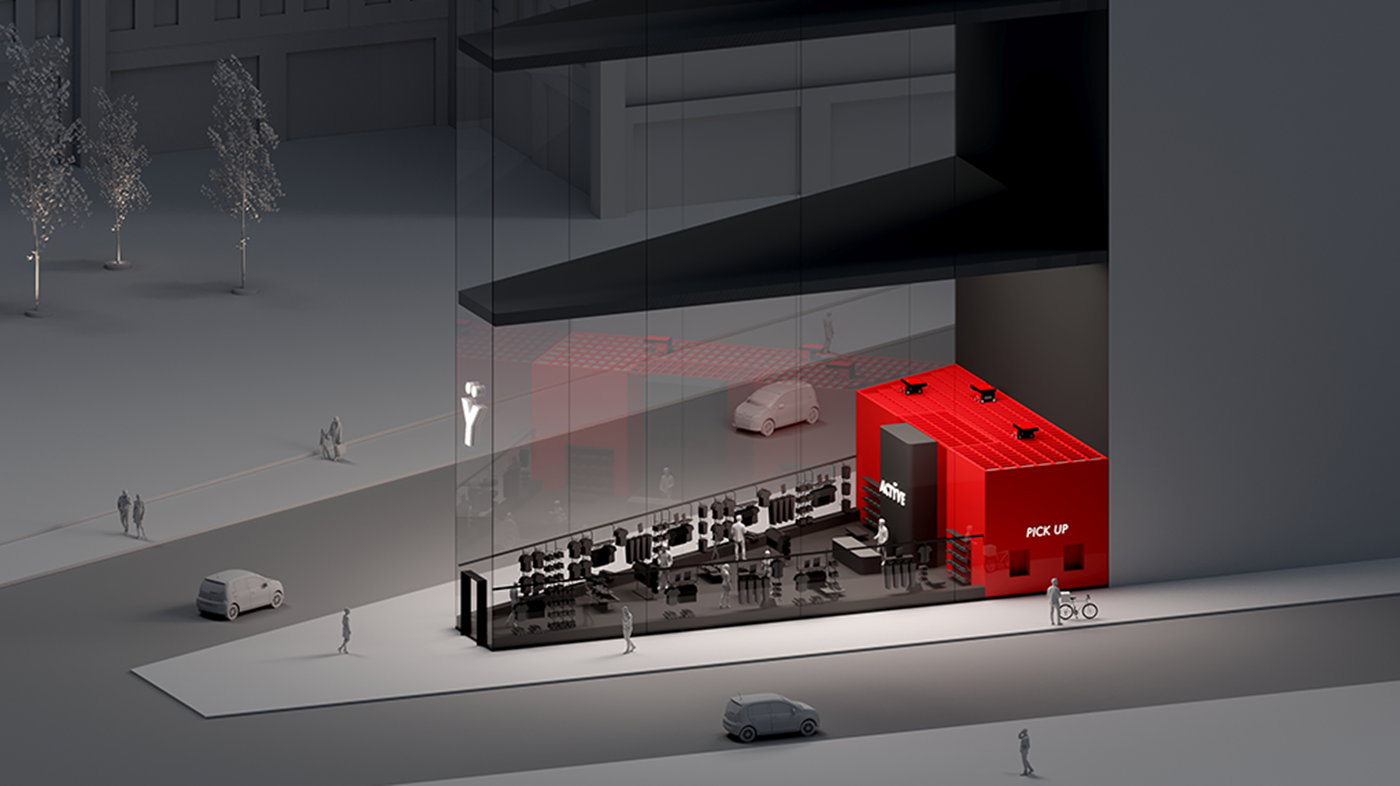

Working with farming companies and grocers, Swisslog can help strengthen the food supply chain, transform abandoned urban buildings into productive growing facilities and contribute to reductions in pollution. We can also play a role in eliminating food deserts and bringing nutritional leafy greens, such as lettuce and spinach, to underserviced communities.

Swisslog is committed to advancing supply chain sustainability with energy efficient solutions and less wasteful processes. Bringing automation to vertical farming is just one example of how we are doing this.

Best-in-class automation

These innovative systems can employ a range of automation technologies and configurations based on the growing process application needs.

• The PowerStore high density storage system.

• The CarryPick robotic shuttle system.

• The Tornado mini load crane

• The Vectura stacker crane