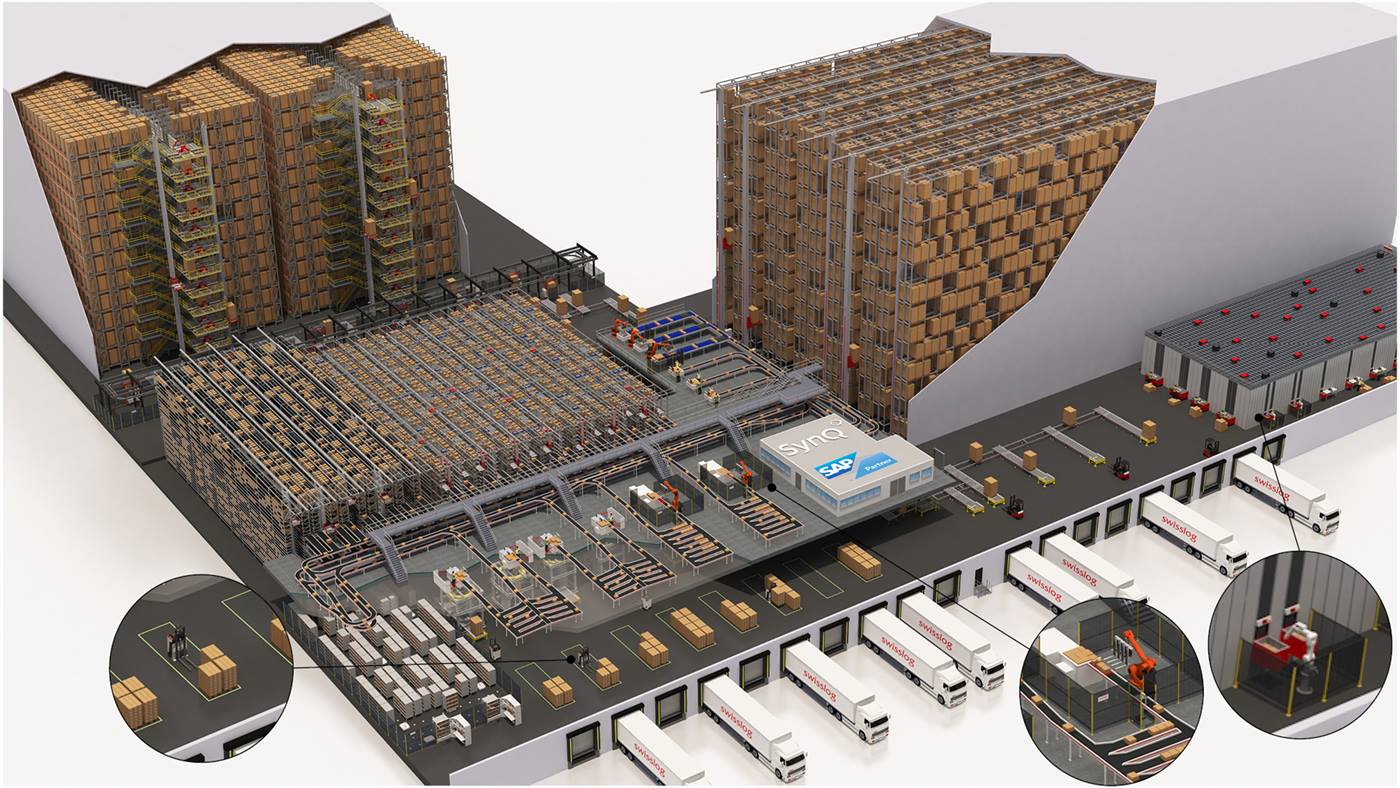

Linfox, Australia: Facility that safely stores dangerous goods

One of the first automations in Australia at Linfox Logistics to store six classes of dangerous goods and achieving over 99% availability

#1 AutoStore integrator to support Linfox

Linfox is leading the way as Asia Pacific’s largest privately-owned logistics company, employing more than 24,000 people across 10 countries. Delivering more than AUD$60 billion a year in goods across a network of more than 200 warehouses, Linfox works with some of the world’s largest and most successful companies. Linfox chose Swisslog due to their knowledge of system availability, functionality and future expansion. Swisslog was able to customise the technology and software to meet the needs of Linfox and its customer. Swisslog is the world’s leading AutoStore integrator with over a decade of AutoStore experience and 200 installed projects in over 20 countries worldwide.

Easy to use SynQ interface

Over 99% availability

AutoStore robots

Storing six classes of dangerous goods

Our valued global consumer goods customer required a bespoke solution to deliver growth through more efficient capacity, productivity, accuracy and speed to market. After an extensive selection process to find an automation partner that understood our customer’s needs, we chose Swisslog.

Partnership with AutoStore continues to grow

Swisslog's strong partnership continues to grow and pushes the boundaries of AutoStore's standard functionality. Swisslog's experience means that tailor-made software and solutions can be engineered to create a customer centric solution. Swisslog works together with AutoStore to globally deliver solutions that generate the greatest gain for our customers.