ANSTO, Australia: Increasing safety and eliminating manual lifting in a high security site

Automated processes has bolstered benefits for health and industry sectors

Australia's Nuclear Science and Technology Organisation

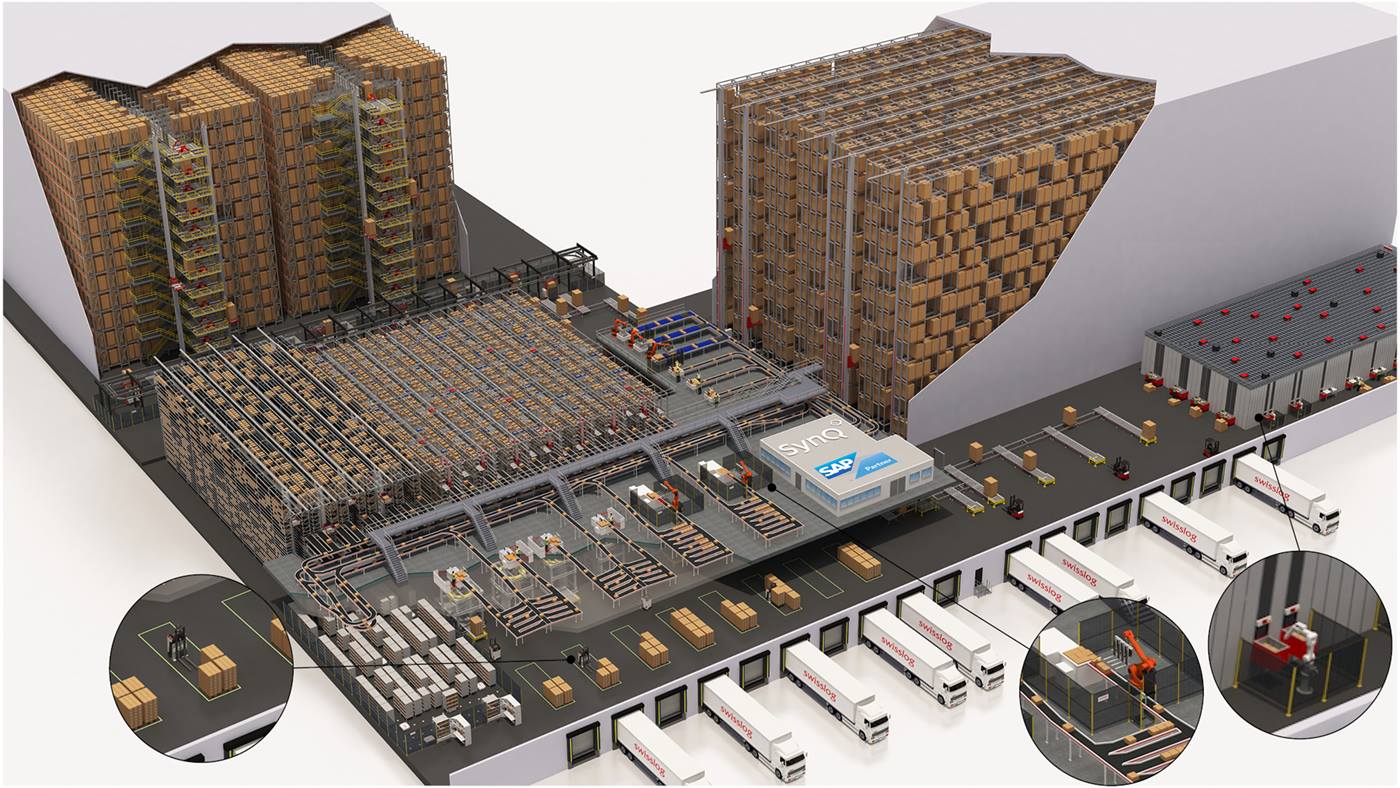

ANSTO conducts some of Australia’s most important national scientific research and operates much of Australia’s landmark and national infrastructure, including one of the world’s most modern nuclear research reactors, OPAL. ANSTO, which also produces nuclear medicine vital to the Australian health industry and undertakes research critical to many other industries, is now using a new Swisslog automated storage and retrieval system (ASRS).

Barrels at the Inspection Station

Safety a priority

The Vectura crane safely storing drums

A customised solution

Partnering with Swisslog was a natural move due to their vast knowledge and experience both locally and internationally and their ability to tailor the solution to meet our needs. This automation has created end-to-end traceability, is seamlessly integrated with our HOST system and has improved overall warehouse productivity