Swisslog automated spare parts warehouse for Komatsu wins ASCLA Supply Chain Management accolade

December 16, 2024

Swisslog and Komatsu have received a Highly Commended recognition at the 2024 Australian Supply Chain and Logistics Award (ASCLA) in the Supply Chain Management category, for a new automated warehouse solution at Komatsu’s new spare parts warehouse in Tarneit, Victoria.

This award category recognises an organisation that has demonstrated significant achievement or improvement within a section or across their entire supply chain.

Swisslog Australia and New Zealand Head of Sales and Consulting, Sean Ledbury, says that Swisslog and Komatsu worked closely together on this forward-thinking project, and this recognition showcases the result of two hardworking teams.

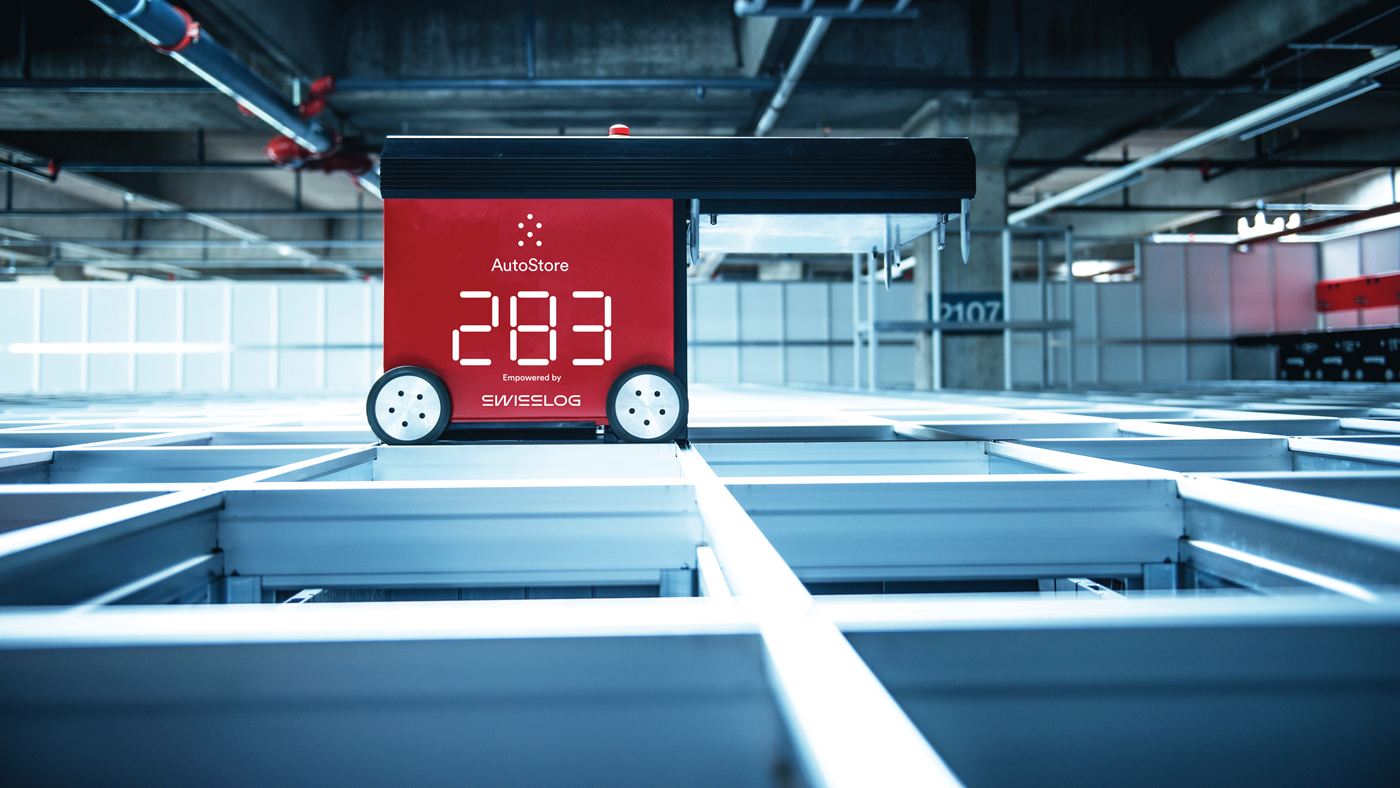

“This Swisslog AutoStore solution is an example of warehouse automation done well. It has improved uptime, energy efficiency, space optimisation, storage and retrieval efficiency, and readiness for future expansion. Based off this successful project and the strong relationship we have built with this leading mining and construction equipment company, Swisslog is now in the process of delivering a second site for Komatsu in North America”, says Ledbury.

Komatsu’s new automated warehouse

The new purpose-built warehouse is designed to store small-to-medium sized parts for machinery used in the construction sector, a major market for Komatsu in Victoria.

“Construction is a demanding sector, so we required a system with high levels of uptime. Seeing AutoStore deliver 99.9% uptime globally, and Swisslog’s local projects regularly seeing higher numbers up to 99.99% gave us the confidence that we will be able to best serve our customers at all times,” said Komatsu General Manager, Warehousing, Hendrik Van Der Merwe.

In addition to the construction sector, Komatsu provides essential equipment, technologies, and services to the mining, energy, government, waste, and quarry industries. The company’s purpose is to create value through manufacturing and technology innovation to empower a sustainable future where people, businesses, and their planet thrive together. Komatsu specialises in the sale of equipment, and the ongoing support of that equipment via the distribution of spare parts, which is where the new Swisslog solution will provide greater efficiencies, allowing Komatsu to deliver better service to customers.

AutoStore is a unique and simple grid-based automation solution that uses robots and bins to quickly process small parts orders. It provides better use of available space than any other automated system thanks to its unique design that enables direct stacking of bins on top of each other and storage of multiple SKUs in a single bin. Over time, the system naturally learns which products have a higher rotation, storing them on the top layer to ensure faster picking times.

Swisslog is one of the world’s leading AutoStore integrators and the largest and most experienced AutoStore integrator in the Australian and New Zealand region, with hundreds of projects worldwide, backed by support, expertise, and software.

“Swisslog has built this warehouse automation system with the capacity to expand as Komatsu expands, which aligns with our growth plans, and enables us to ramp up capacity to meet demands,” said Van Der Merwe.

Contact

Swisslog AG

Gabriel Meier

T +41 76 825 21 02

M gabriel.meier@swisslog.com

About Swisslog

Swisslog delivers data-driven & robotic solutions for your logistics automation alongside reliable, modular service concepts. Collaborating with forward-thinking companies, we are committed to setting new standards in warehouse automation to provide future-proof products and solutions. As part of the KUKA Group, our customers trust the competence of our passionate employees – more than 15,000 people working across the globe.

www.swisslog.com & www.kuka.com