Swisslog Automation Solution to Increase Storage Density in Third Radwell International Facility

Swisslog, leading provider of best-in-class warehouse automation and software, has announced that Radwell International will install a Swisslog automation solution in its Glendale, AZ facility.

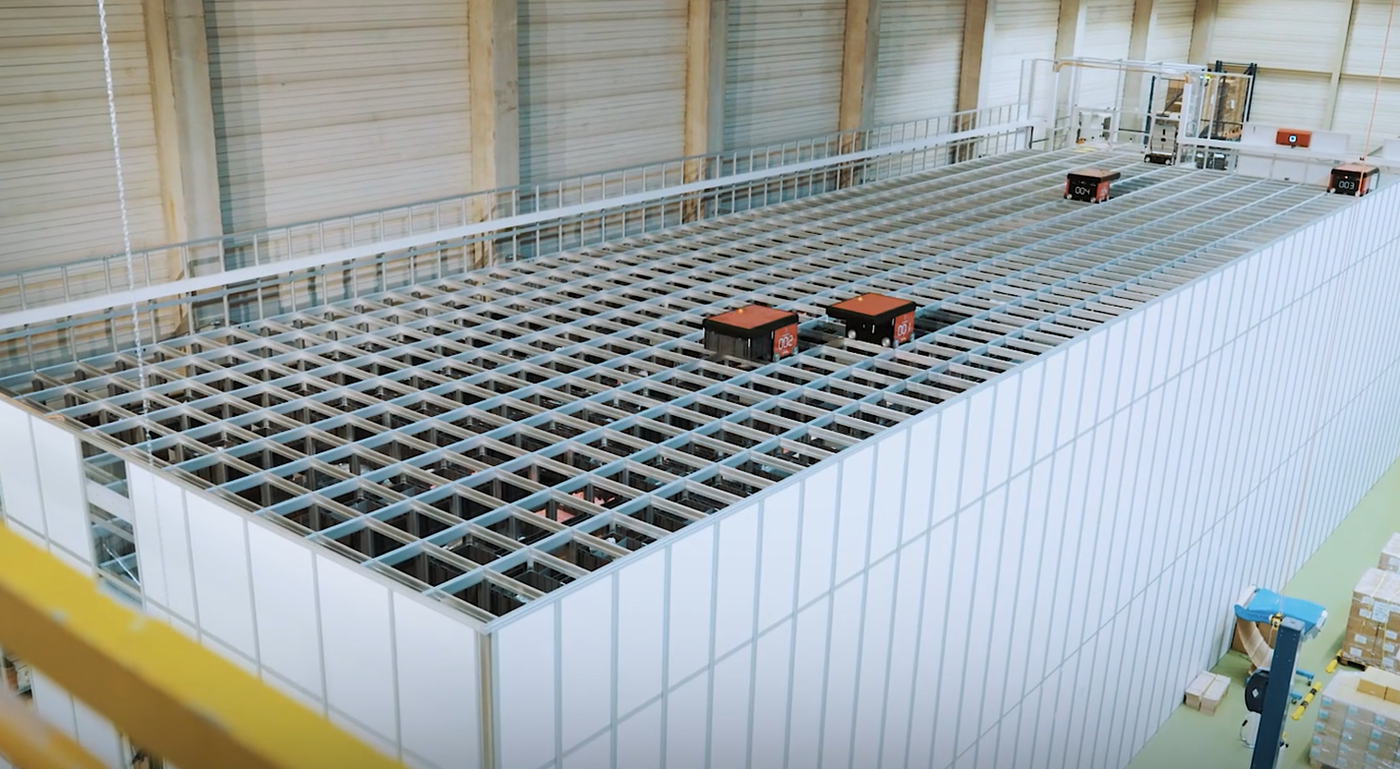

October 25, 2022, Newport News, VA – Swisslog, leading provider of best-in-class warehouse automation and software, has announced that Radwell International will install a Swisslog automation solution in its Glendale, AZ facility. Designed by Swisslog experts, the solution features the AutoStore system optimized by Swisslog’s SynQ software. The facility is expected to be operational by November 2023.

“Radwell was so pleased with the successful AutoStore implementations in its New Jersey and Texas distribution centers, the company decided to again work with Swisslog and designed their newest regional distribution in Arizona around the Swisslog automation system,” said Markus Schmidt, President of Swisslog Americas. “We are honored that Radwell is continuing our relationship, and we once again look forward to working closely with the company to install this next generation order fulfillment solution.”

The design of the system, which contains 42,915 bins and 40 robots, is based on achieving maximum quantity of bins in the given footprint. It operates on synchronized intelligence from Swisslog’s SynQ software, which provides warehouse management, material flow and automation control system functionality in a single, modular platform that integrates seamlessly with host systems and other warehouse software. For this installation, Radwell chose to enrich the software by including optimized small parts functionality and inventory consolidation/compacting functionality to increase the storage density of the system.

“Swisslog warehouse automation is an incredible solution that we have enjoyed having in both our New Jersey and Texas distribution centers. We are excited to be integrating this system into our Glendale, AZ facility, which will be serving as our West Coast distribution center. This will help accelerate the growth of our footprint on the west coast,” said Kyle Rodier, Radwell Branch General Manager. “Radwell is a very unique business with hundreds of thousands of different SKUs in all types of shapes and sizes. The Swisslog automation experts customize their solution to exactly fit our unique needs.”

Radwell International supports its customers with a broad range of new and used industrial products including industrial automation, MRO, pneumatic, motion, electronic, hydraulic, HVAC and electrical control equipment for plant floors and facilities. The company also provides component-level repair for all industrial electronic and electrical equipment, and buys new and used surplus for resale.

Across all applications, Swisslog has deployed more AutoStore systems than any other organization. Earlier this year, Swisslog announced it had passed 300 AutoStore projects worldwide, showing why it is the industry’s leading and most trusted AutoStore integrator that understands exactly how to optimize configurations to fit the customer’s need.

“Radwell was so pleased with the successful AutoStore implementations in its New Jersey and Texas distribution centers, the company decided to again work with Swisslog and designed their newest regional distribution in Arizona around the Swisslog automation system,” said Markus Schmidt, President of Swisslog Americas. “We are honored that Radwell is continuing our relationship, and we once again look forward to working closely with the company to install this next generation order fulfillment solution.”

The design of the system, which contains 42,915 bins and 40 robots, is based on achieving maximum quantity of bins in the given footprint. It operates on synchronized intelligence from Swisslog’s SynQ software, which provides warehouse management, material flow and automation control system functionality in a single, modular platform that integrates seamlessly with host systems and other warehouse software. For this installation, Radwell chose to enrich the software by including optimized small parts functionality and inventory consolidation/compacting functionality to increase the storage density of the system.

“Swisslog warehouse automation is an incredible solution that we have enjoyed having in both our New Jersey and Texas distribution centers. We are excited to be integrating this system into our Glendale, AZ facility, which will be serving as our West Coast distribution center. This will help accelerate the growth of our footprint on the west coast,” said Kyle Rodier, Radwell Branch General Manager. “Radwell is a very unique business with hundreds of thousands of different SKUs in all types of shapes and sizes. The Swisslog automation experts customize their solution to exactly fit our unique needs.”

Radwell International supports its customers with a broad range of new and used industrial products including industrial automation, MRO, pneumatic, motion, electronic, hydraulic, HVAC and electrical control equipment for plant floors and facilities. The company also provides component-level repair for all industrial electronic and electrical equipment, and buys new and used surplus for resale.

Across all applications, Swisslog has deployed more AutoStore systems than any other organization. Earlier this year, Swisslog announced it had passed 300 AutoStore projects worldwide, showing why it is the industry’s leading and most trusted AutoStore integrator that understands exactly how to optimize configurations to fit the customer’s need.