Swisslog automation helps Master Electronics champion growth by maximizing capacity and productivity in existing distribution center

Swisslog, leading provider of best-in-class warehouse automation and software, has announced that Master Electronics, a leading global authorized distributor of electronics components, will deploy Swisslog automation to help modernize and streamline fulfillment in its existing warehouse to meet growing demand.

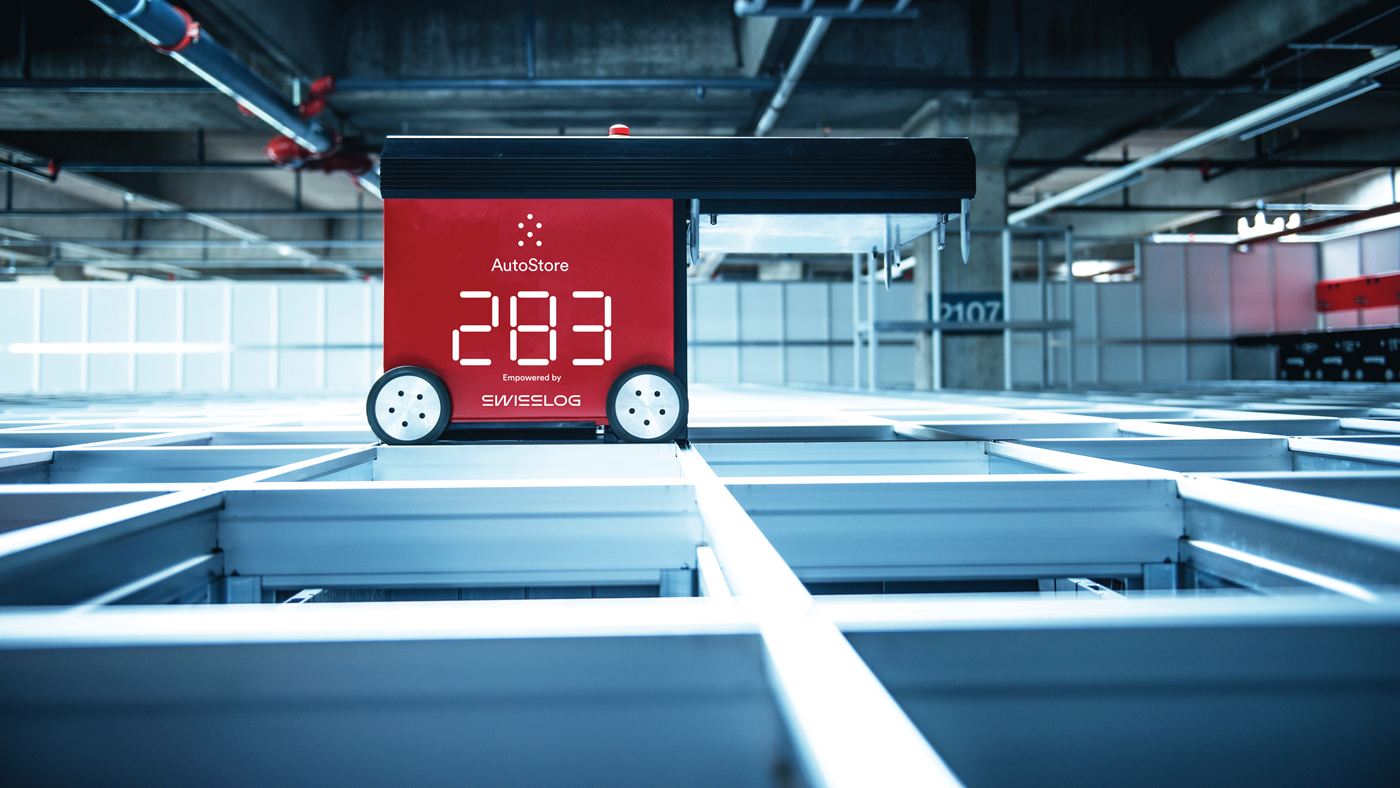

Configured by Swisslog’s automated fulfillment experts, the system brings together AutoStore and picking stations, optimized by Swisslog’s SynQ software. Its bins are electrostatic discharge (ESD) compliant to protect Master’s sensitive inventory from static electric discharge. Swisslog worked closely with the electronics distributor to adapt the system to the parameters of the existing building to ensure it delivered the increased storage capacity and higher throughput. The modular technology is being implemented through an approach that will minimize disruption to operations, to help ensure fulfillment capabilities are maintained during installation.

“Swisslog’s expertise and vast experience in the automation space has been indispensable. Our position in the industry is unique and they have been able to create a completely custom solution that leverages our strengths while overcoming obstacles,” said Master Electronics Vice President of Global Logistics and Distribution, Gerone Blomgren. “Along with providing an automation system that will enable continued growth while meeting increasing customer demand without the challenge and disruption of building a new facility, Swisslog is helping us create a more engaging environment for our DC associates.”

“Our Swisslog automation experts are excited to work with Master Electronics to help them modernize and future-proof their operations while extending the capacity and life of their existing facility,” said Colman Roche, Vice President of E-Commerce and Retail, Swisslog Americas. “With the growth in e-commerce, many warehouses that were never designed for carton handling or smaller order size picking are being required to support those functions. We continually work with companies like Master Electronics to configure and install automation solutions that can help transform existing warehouse space to maximize storage capacity and keep products moving.”

Swisslog recently released a new white paper ("Implementing Warehouse Automation in Brownfield Sites") that explains how certain automation systems can increase storage capacity and throughput of existing warehousing and distribution facilities.

About Swisslog

Swisslog delivers data-driven & robotic solutions for your logistics automation alongside reliable, modular service concepts. Collaborating with forward-thinking companies, we are committed to setting new standards in warehouse automation to provide future-proof products and solutions. As part of the KUKA Group, our customers trust the competence of our passionate employees – more than 14,000 people working across the globe.