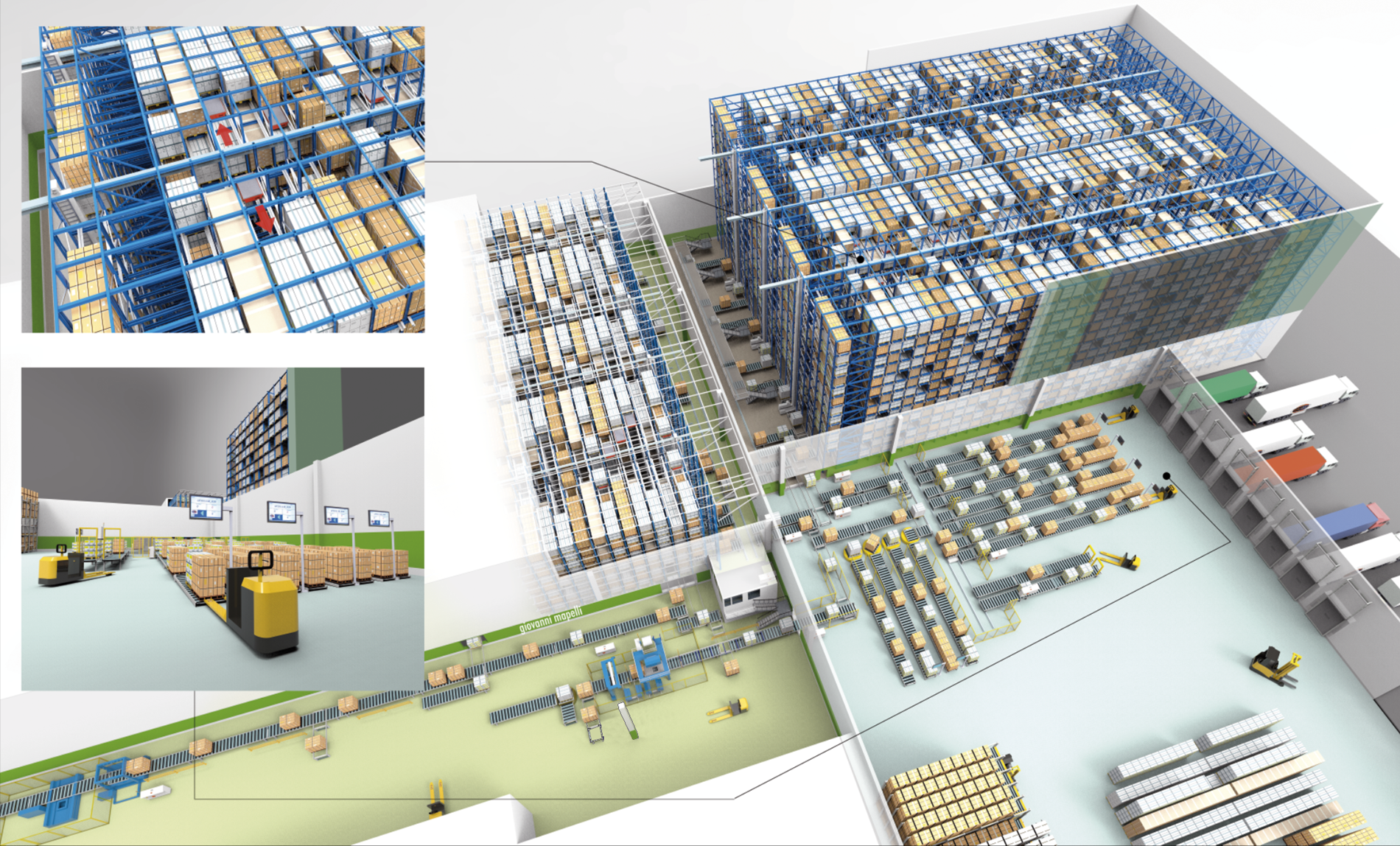

Increasingly automated logistics

The production lines in Parma went from 2 to 3 and the storage area was doubled. In terms of volumes, there are 100 tons of tomato a day, 25 tons of basil are processed here and 340 jars are produced per minute, 20 thousand / hour, 100 million in a year, for a total of more than 250 recipes and more than 800 items in 34 different jar formats.

Once the third production line is fully operational, the goal will be to produce 13 million jars a month, 160 million a year.