Recovering Quickly

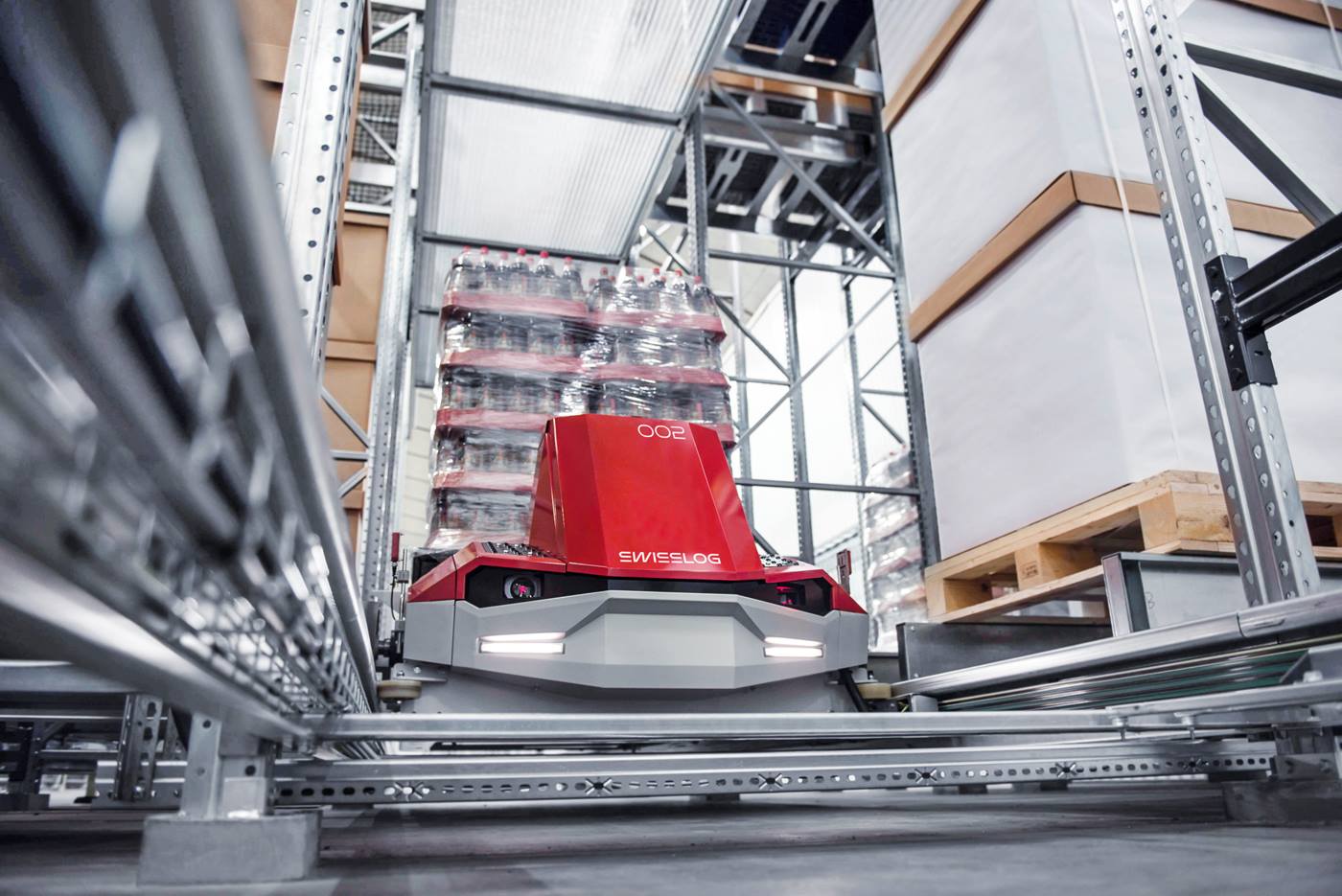

It’s no secret that multiple system integrators use Swisslog technologies in their solutions because of the performance and reliability those technologies deliver. But while those integrators may deliver the same technologies we do because they buy them from us, they can’t match our approach to lifecycle support.

Warehouse automation systems are complex mechanical systems operating in demanding environments and the software that supports them is equally complex. Expecting every component to operate without ever needing service is obviously unrealistic.

Achieving the highest possible availability for these solutions requires a high level of specific expertise and skilled technical support specialists. It also requires an organizational culture that prioritizes lifecycle support and a commitment to making it easy to access that support.

Swisslog has built a robust service offering that extends from resident engineers who specialize in equipping internal teams with the knowledge and skills they need to maintain our solutions, to a network of field service specialists strategically located globally to provide fast response to service issues that can’t be resolved by internal teams. Our 24 x 7 software support makes it easy for our customers to connect directly with specialists who understand their solution.

We’re also working to use system data to enable proactive maintenance strategies that reduce planned and unplanned downtime, and our service specialists work with our customers to optimize automation performance and process efficiency as requirements change.

It’s an approach to support that can make the difference between a solution that achieves your availability goals and one that doesn’t.

Warehouse automation systems are complex mechanical systems operating in demanding environments and the software that supports them is equally complex. Expecting every component to operate without ever needing service is obviously unrealistic.

Achieving the highest possible availability for these solutions requires a high level of specific expertise and skilled technical support specialists. It also requires an organizational culture that prioritizes lifecycle support and a commitment to making it easy to access that support.

Swisslog has built a robust service offering that extends from resident engineers who specialize in equipping internal teams with the knowledge and skills they need to maintain our solutions, to a network of field service specialists strategically located globally to provide fast response to service issues that can’t be resolved by internal teams. Our 24 x 7 software support makes it easy for our customers to connect directly with specialists who understand their solution.

We’re also working to use system data to enable proactive maintenance strategies that reduce planned and unplanned downtime, and our service specialists work with our customers to optimize automation performance and process efficiency as requirements change.

It’s an approach to support that can make the difference between a solution that achieves your availability goals and one that doesn’t.