Safety meets efficiency: EN619 compliance with Swisslog’s pallet conveyor

Elevating conveyor safety

EN619:2022 sets comprehensive safety requirements for equipment used in mechanical handling of unit loads such as pallet transport conveyors. Covering design, transport, installation, commissioning, operation, adjustment, maintenance and service and cleaning, the standard aims to minimize risks like mechanical failure, entrapment, and load instability. Key features include mandatory guarding, emergency stops, load stability controls, and fail-safe mechanisms—especially relevant for high-speed, heavy-duty pallet conveyors.

EN619:2022 also introduces and updates the previous edition considering an area-based safety concept, dividing environments into public area, working/traffic area, restricted/maintenance area, and danger area. Each zone has tailored safety requirements, with special attention to danger zones where human exposure is highest. The area concept is optional but recommended for complete compliance.

Adhering to EN619 not only ensures legal compliance but also reinforces a commitment to safety and operational excellence.

ProMove’s commitment to EN619:2022 compliance

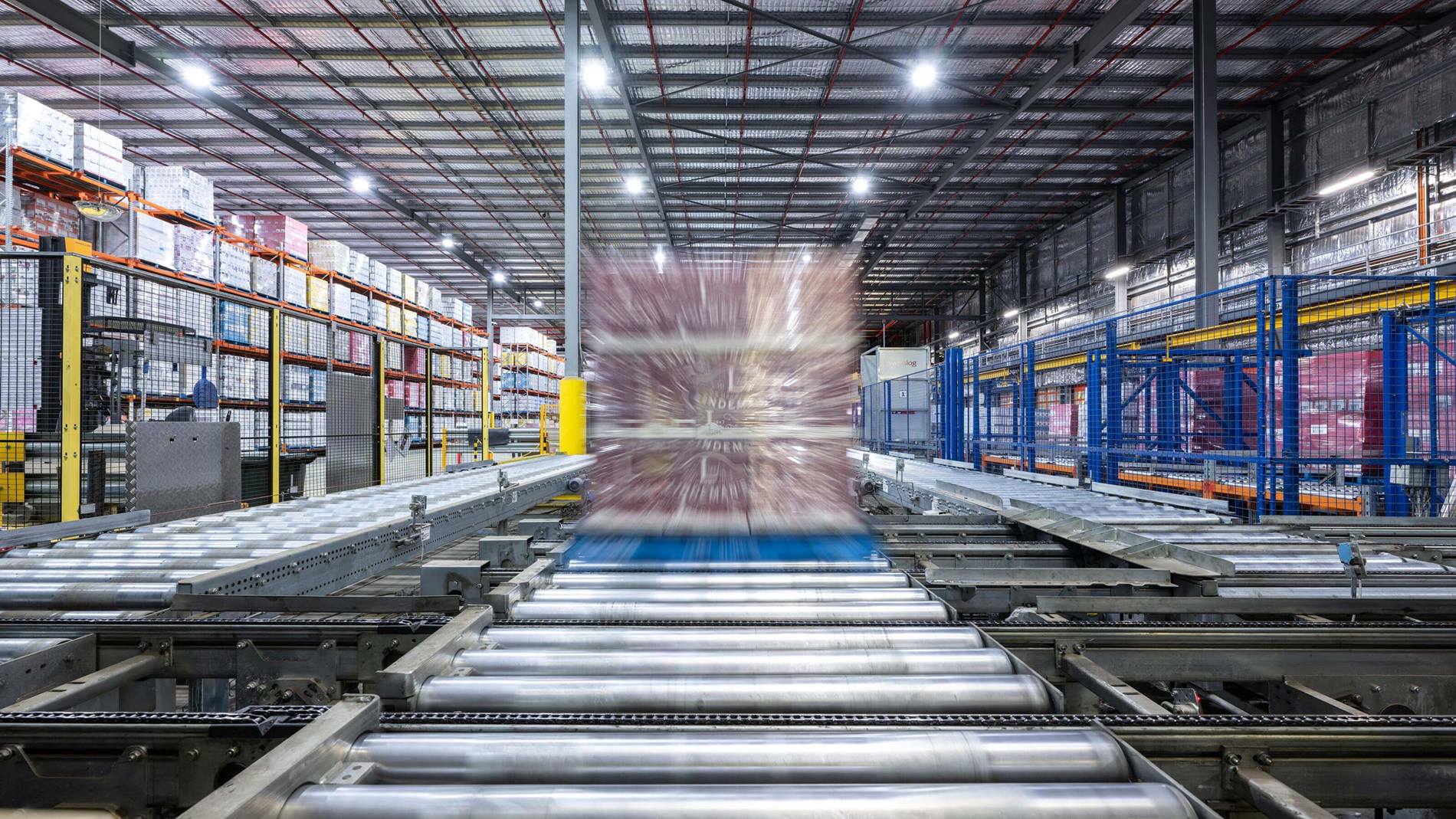

Swisslog’s ProMove conveyor system exemplifies alignment with EN619:2022 safety standards, integrating advanced engineering solutions to benefit both operators and integrators of conveyor solutions. By prioritizing risk reduction and operational reliability, ProMove incorporates a suite of robust safety features designed for modern material handling environments.

Among its key compliance mechanisms are precision-engineered protective gaps that prevent body part injury, fulfilling the strict requirements of EN ISO 13854:2019. The system’s compact starter technology as an electrical equipped cabinet ensures gentle load management, while pre-wired sensors and motors enable fast, error-resistant installation and commissioning, minimizing human contact with electrical components and greatly reducing the potential for onsite mishaps.

ProMove also boasts adjustable-speed motors that optimize safety, alongside innovative drive techniques that enhance load stability and minimize mechanical wear. Real-time monitoring capabilities further empower operators to react swiftly to any operational anomalies, maintaining a safe working environment across all conveyor zones.

Consequently, Swisslog’s proactive approach not only safeguards personnel but also streamlines operational processes, with main safety features:

- Minimum gaps to prevent body part injury

- Compact starter technology for gentle load management

- Pre-wired sensors and motors for rapid setup for safe installation and commissioning, reducing on-site wiring errors and minimizing human exposure to these components

- Drive techniques that stabilize loads and reduce wear

This commitment to the highest safety standards extends not only to newly deployed ProMove solutions, but also to the upgrade and modernization of existing installations, ensuring that both current and legacy systems benefit from enhanced protective features, advanced monitoring technologies, and the latest regulatory compliance measures to safeguard personnel and optimize operational reliability.

Upgrade path for legacy ProMove conveyor systems

Existing ProMove systems can be seamlessly upgraded to meet EN619:2022 compliance through a comprehensive retrofit process. This enhancement pathway includes the installation of advanced motors engineered to prevent unintended movement and reduce risks such as crushing or instability. Safety can be strengthened by incorporating compact starters, which minimize hazards during installation and commissioning.

To bring control systems up to the latest standards, legacy units are updated with Siemens platforms featuring robust safety logic, delivering greater reliability and automated protective responses. Safety in day-to-day operation is elevated by fitting pre-tested sensor kits, which enable real-time monitoring and rapid intervention should a fault be detected.

These retrofit solutions empower warehouse operations to extend the benefits of EN619:2022—streamlined safety procedures, reduced downtime, and simplified system commissioning—to both new and legacy ProMove conveyor installations. With tailored upgrades and expert support, every conveyor environment can achieve a higher standard of personnel protection and operational excellence with the main features:

- Replacing motors with efficient, compliant units

- Adding compact starters to minimize risk during installation

- Updating control systems to Siemens platforms with improved safety logic

- Installing pre-tested sensor kits for enhanced safety in operation

Area-based safety concept

To ensure safe and compliant conveyor system design, EN619:2022 introduced an area-based approach that categorizes environments into zones with tailored safety requirements. EN619:2022 defines four distinct areas, each with specific safety requirements for conveyors depending on their placement. While using the area concept is optional, EN619:2022 links its requirements to these areas, making it the preferred approach for compliance. Especially for danger areas, where people can be exposed to danger during the operation of the machine, specific requirements have to be taken into account. Swisslog is actively implementing the EN619:2022 area-based safety concept across its conveyor systems, particularly within the ProMove platform, to ensure full compliance and enhance operational safety.

As material handling environments grow more complex and demanding, safety must evolve in tandem. EN619:2022 sets a new benchmark for conveyor system safety. Through precision engineering, intelligent monitoring, and a proactive upgrade path for legacy systems, ProMove empowers businesses to create safer, more efficient operations. By embracing the area-based safety concept and integrating robust compliance features, Swisslog demonstrates a clear commitment to protecting personnel while optimizing performance. Whether deploying new systems or modernizing existing ones, aligning with EN619:2022 is not just about meeting regulations; it´s about leading with safety and reliability at the core. To learn more, contact us.

Discover 6 proven strategies to reduce pallet storage costs in the Food & Beverage supply chain. Learn how smarter warehouse design and SKU optimization can boost efficiency and cut expenses.