AutoStore: Space saving storage and order picking system for small parts. Now available for deep-freeze applications

Do you want to store a large number of small parts while increasing storage density and remaining very flexible? AutoStore is a highly efficient robotized storage and order processing solution that integrates easily into existing buildings.

AutoStore: Compact storage & picking system for multi-temperature management including deep freeze

AutoStore: Product handling with the highest storage density

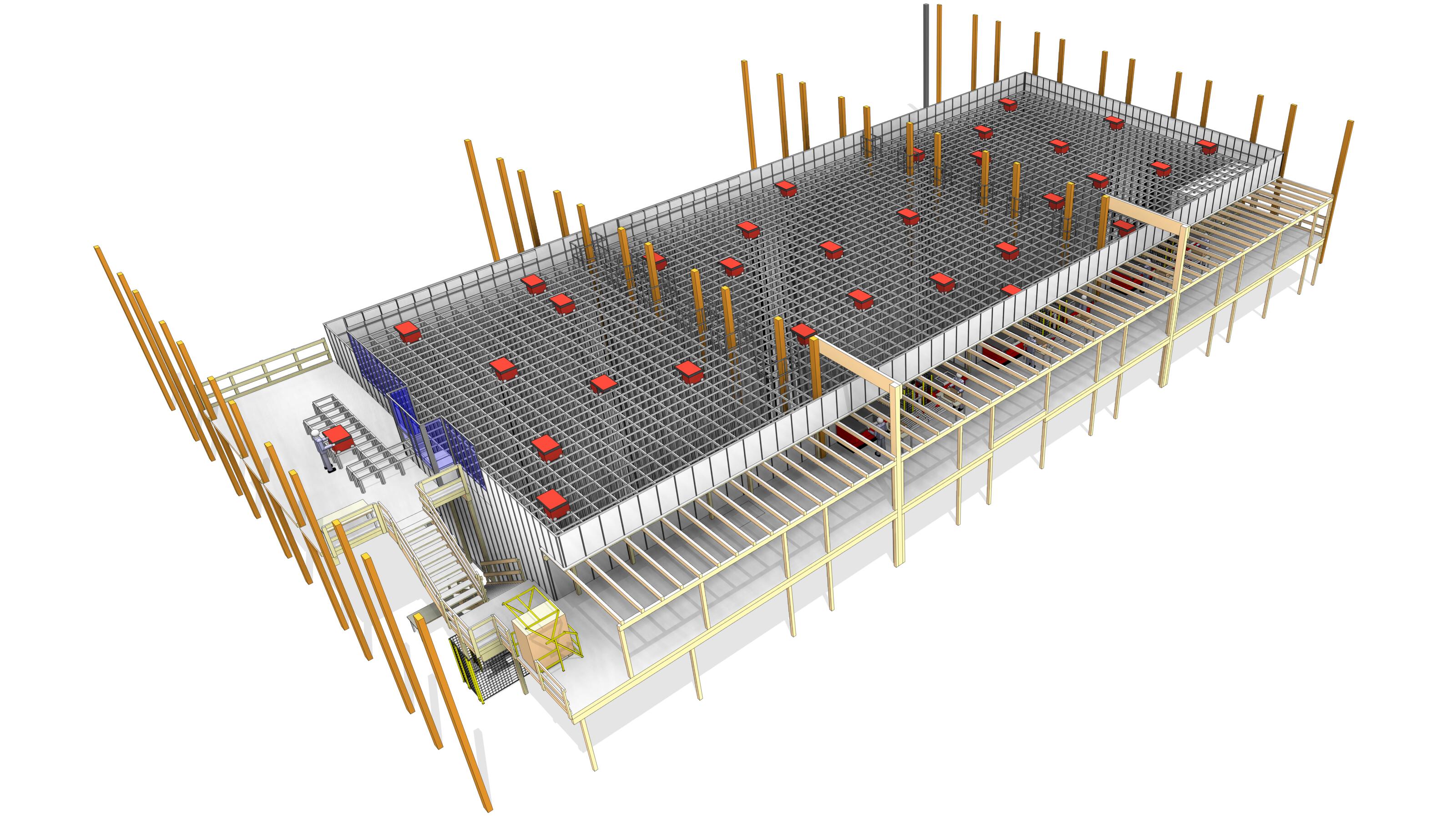

AutoStore is a unique and simple solution that uses robots and bins to quickly process small volume orders in ambient and chilled temperature zones. It provides better use of available space than any other automated system thanks to its unique design that enables direct stacking of bins on top of each other and storage of multiple SKUs in a single bin.

Over time, the system naturally learns which products have a higher rotation, storing them on the top layer to ensure faster picking times.

AutoStore: Now available for deep freeze handling at -25°C.

Innovative solution designs by Swisslog extend the AutoStore Multi-Temperature Solution (MTS) to combine multiple temperature zones with the AutoStore system:

- Ambient

- Cold / fresh

- Frozen

> Learn more about the PROJECT IN FRANCE: La Réserve des Saveurs

AutoStore: Meeting the throughput demands of the modern warehouse

AutoStore’s speed, density, and flexibility make it ideal for high-volume retail. It offers the highest order fulfillment per square meter of any G2P solution and can support over 20,000 picks per hour.

With Swisslog, you get more throughput for your investment and greater adaptability. Our SynQ software boosts delivery speed by up to 20% and enables multi-order picking from a single bin. You can shift priorities between throughput and density, route specific order types to designated ports, and manage orders based on shipping deadlines to avoid delays.

AutoStore: Modular design with Swisslog special features

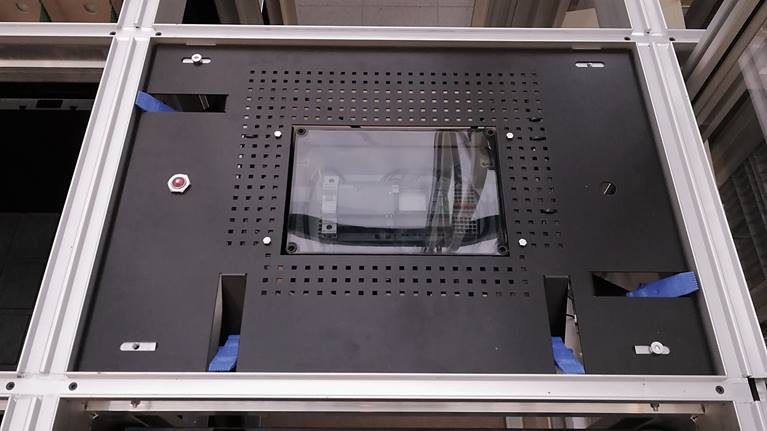

Whatever your building looks like, AutoStore can be optimally designed in and around structures such as columns, floor height differences or other spatial peculiarities. Wide tunnels or narrow bridges are also possible. Use the dots below to discover the components of AutoStore and other extras Swisslog has to offer...

What if you could double storage capacity without any additional construction? This is possible with AutoStore!

Explore AutoStore pictures from Swisslog. Swipe to see more.

Swisslog can provide standard stand-alone solutions to integrated systems with conveyor systems or other subsystems. Highly efficient picking modules driven by Swisslog SynQ software.

AutoStore: future-proofed system with robots

AutoStore’s modular, fully scalable design, makes the system future-proof: To increase throughput simply add more robots. Its flexibility also makes it easy to integrate into existing buildings without needing any additional construction work. The system’s unique redundancy means there is no single point of failure. If one robot breaks down, another takes over its tasks.

Each robot is extremely energy efficient, using just 0.1 kW of energy per hour – 6 robots use the same as a toaster! This low energy consumption combined with low maintenance costs makes for a very favorable total cost of ownership (TCO). With a low investment, AutoStore achieves efficient processing at integrated goods-to-person workstations. People don’t need to walk long distances to pick products, the robots deliver goods directly to pick stations to reduce picking times.

- With more than 400 projects worldwide, we are the AutoStore experts and know the challenges our customers face.

- System easily integrates into other Swisslog subsystems including conveyors, robots and software, thanks to predefined standards.

- Ready for future growth: AutoStore can be used with manual picking stations or combined with Swisslog’s ItemPiQ robot cell, giving you the option to automate picking step-by-step.

- Integrated into Swisslog’s Software SynQ. In addition to the core processes you get access to analytical tools. These will help you evaluate better and make smart decisions in your warehouse.

- Proven algorithms, processes and ergonomic operator screens enable maximum performance from the overall system. Standard connection to SAP/EWM ensures reduced integration costs and increased flexibility in labor planning.

Want more information on AutoStore by Swisslog?

If you want more technical details on AutoStore, follow the link to download our factsheet. Our e-book also provides and overview of the technology, configuration options and key learnings from AutoStore users.