At Our Stand

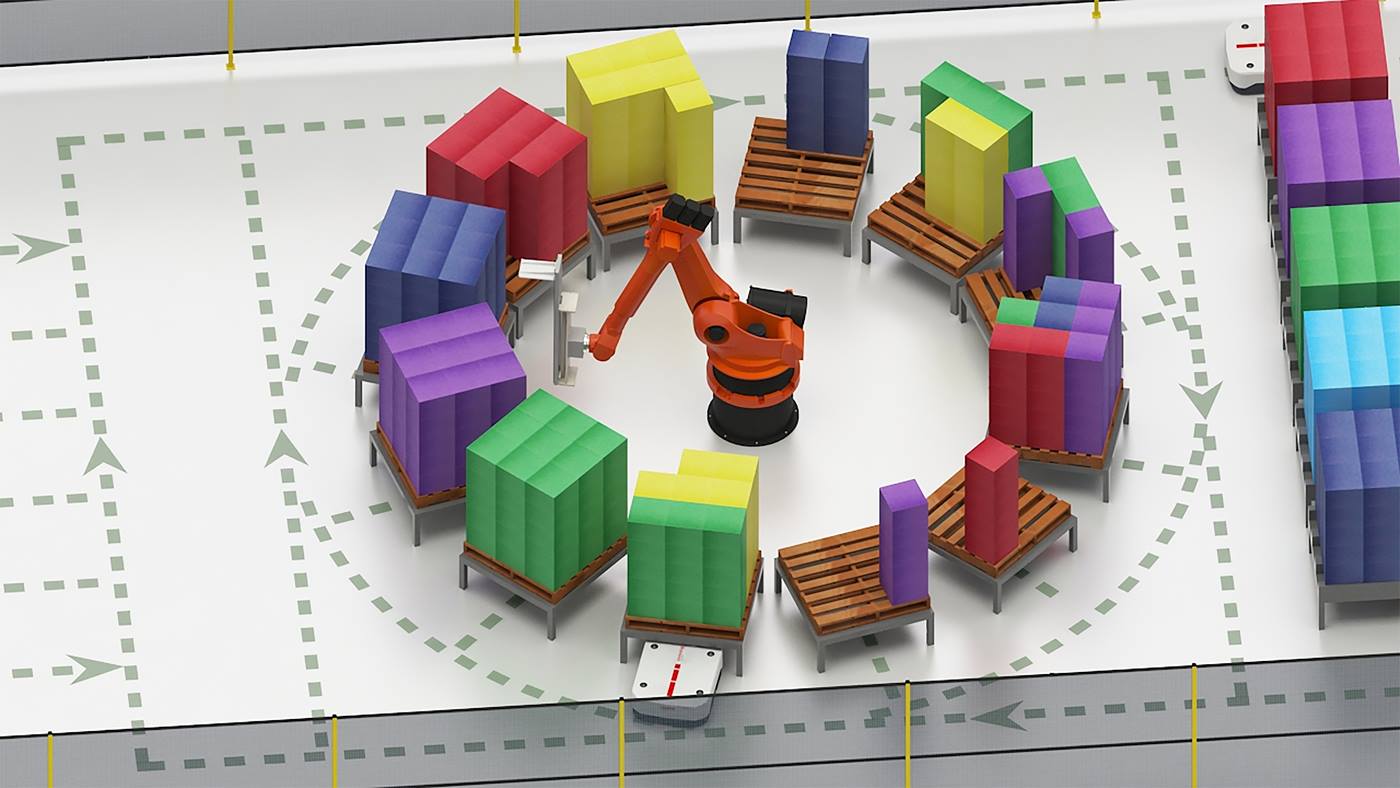

Experience Swisslog and KUKA's smart intralogistic solutions and explore cyberphysical systems with our virtual reality technologies that combine warehouse automation with robotics. Discover the new era of robotics with KUKA's collaborative robot as well as augmented reality applications. Speak to one of our experts to discover how your business can benefit from a modular and automated solution that will grow with your business.

Discover Industry 4.0 applications with KUKA Connect, which is the newest IoT solution for smart manufacturing and a cloud-based software platform that allows users to access analytics of their KUKA robots from any device at any time. Furthermore, explore how SynQ is using Industry 4.0 principals to provide condition monitoring and digital shadowing to shape the future of your warehouse efficiencies.

Click here to register.