Pengo, Italien: Logistik-Innovation für effiziente und nachhaltige Distribution

Entdecken Sie, wie Pengo seine Logistik mit automatisierten Lösungen transformiert hat, um seine Effizienz, Flexibilität und die Nachhaltigkeit zu verbessern. ↓

Dank eines weltweiten Lieferantennetzwerks und fortschrittlicher Logistik gewährleistet Pengo eine zeitnahe Versorgung und effizientes Auftragsmanagement. Die Einführung automatisierter Technologien wie dem AutoStore-System spiegelt das kontinuierliche Engagement des Unternehmens für Innovation, Nachhaltigkeit und stetige Verbesserung der Arbeits- und Servicequalität wider.

In einem globalen Umfeld, das von komplexen Lieferketten, unterschiedlichen Produktionsquellen und zunehmend spezifischen Anforderungen geprägt ist, haben wir uns entschieden, in Automatisierung zu investieren, um unsere Distributionsprozesse zu stärken.

Die Herausforderung

Für Pengo wurde es notwendig, die Lagerkapazität zu erhöhen und das Bestandsmanagement in einem zunehmend komplexen globalen Lieferkettenumfeld zu verbessern. Die Herausforderung bestand nicht nur darin, die Lagerfläche zu erweitern, sondern dies unter Berücksichtigung von Effizienz, Rückverfolgbarkeit und Nachhaltigkeit zu tun.

Darüber hinaus war es entscheidend, operative Flexibilität und Servicekontinuität zu gewährleisten – auch während saisonaler Spitzen und unvorhersehbarer Marktdynamiken.

Die Lösung

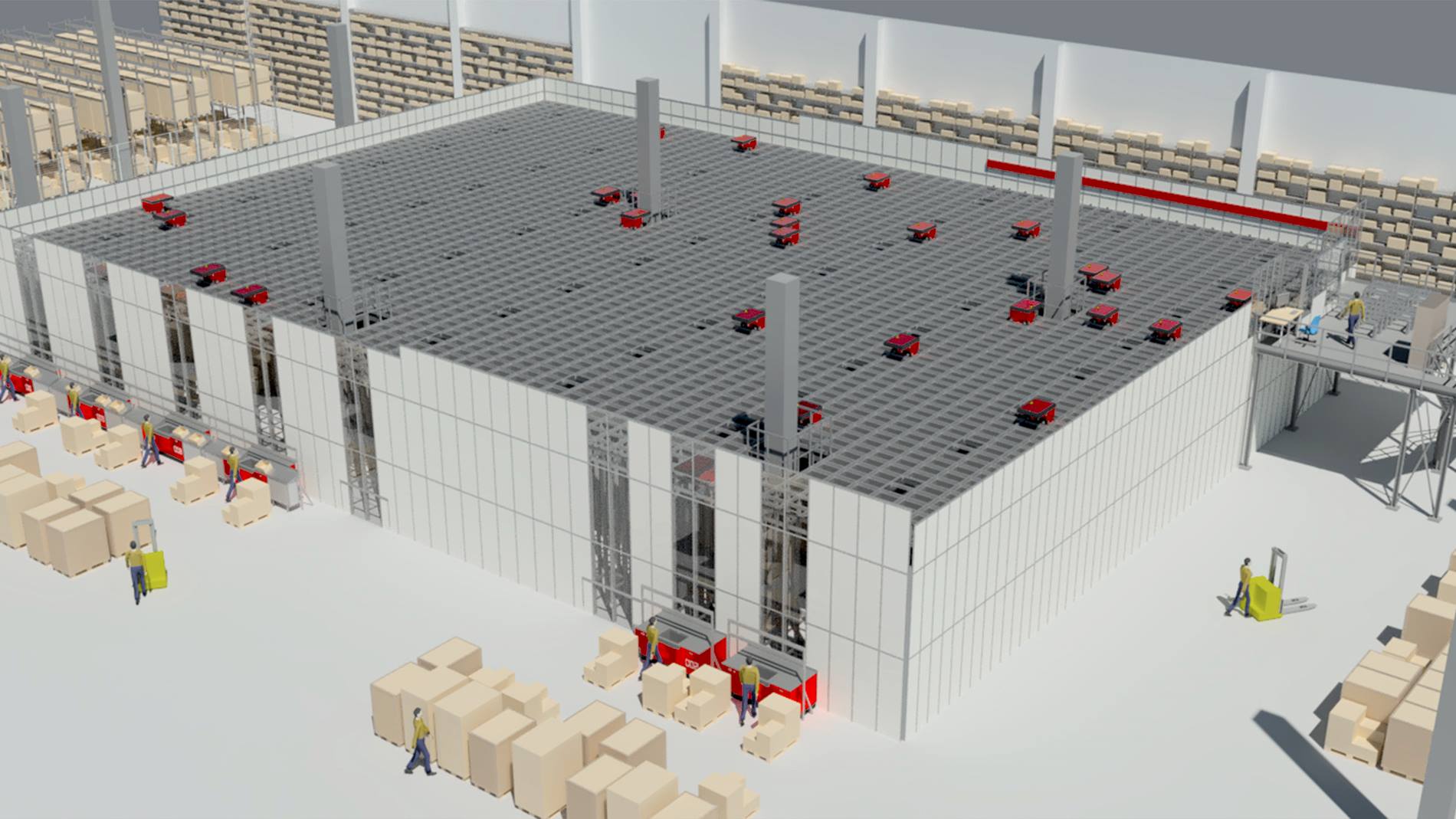

Pengo setzte auf ein integriertes und technologisch fortschrittliches Logistikmodell, um den Herausforderungen bezüglich Kapazität, Effizienz und Nachhaltigkeit zu begegnen. Der Betrieb ist auf zwei Ebenen aufgeteilt: eine 40.000 m² große Plattform für Paletten und eine 20.000 m² große zentrale Plattform für Einzelaufträge. Das Unternehmen implementierte ein automatisiertes System mit Swisslogs AutoStore, das 30 Roboter und 35.000 Behälter umfasst, um Raumnutzung und Genauigkeit zu optimieren.

Dank der Integration von WMS (Warehouse-Management-System) und WCS (Warehouse-Control-System) mit Ware-zur-Person-Lösungen laufen die Logistikprozesse in einem kontinuierlichen und synchronisierten Fluss. Das System kann bis zu 6.000 Auftragspositionen pro Tag bearbeiten und dabei hohe Standards bei Rückverfolgbarkeit, Ergonomie und Arbeitssicherheit aufrechterhalten.

Fortschrittliche Technologie für die Logistik

Pengo nutzt Swisslogs AutoStore-System zur Optimierung von Lagerung und Auftragsvorbereitung. Integriert mit Swisslogs WMS ermöglicht es die automatisierte und präzise Steuerung von Ware-zur-Person-Prozessen.

Dieses technologische Ökosystem gewährleistet hohe Produktivität, Rückverfolgbarkeit und Sicherheit und passt sich problemlos an künftige Erweiterungen und operative Veränderungen an.

Die Ergebnisse

Dank der Integration fortschrittlicher Logistiktechnologie hat Pengo seine Effizienz, Genauigkeit und Lagerkapazität gesteigert sowie die Auftragsvorbereitungszeiten verkürzt.

Das Unternehmen kann nun auch während saisonaler Spitzen operative Kontinuität gewährleisten und hat gleichzeitig Sicherheit und Ergonomie am Arbeitsplatz verbessert. Dieser Ansatz hat Pengos Wettbewerbsfähigkeit gestärkt und unterstützt nachhaltiges und innovationsorientiertes Wachstum.

Kennzahlen

- AutoStore-Volume: 1.190 Kubikmeter

- Anzahl AutoStore-Behälter: 35.000

- Anzahl AutoStore-Roboter: 30

- In AutoStore verwaltete Referenzen: ca. 15.000

- Täglich verarbeitete Volumina der Plattform: 6.000 Positionen/Tag