Automated guided vehicles AGV: The mobile solution of the future

Swisslog has been implementing customized AGV solutions for more than 45 years. Automated guided vehicles are significantly more flexible than fixed installations, and are also demonstrably lower cost above a certain layout size.

AGV: The flexible alternative to fixed installations

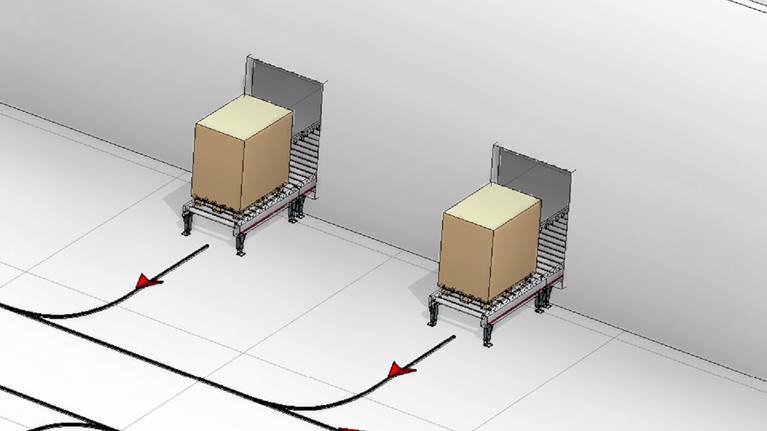

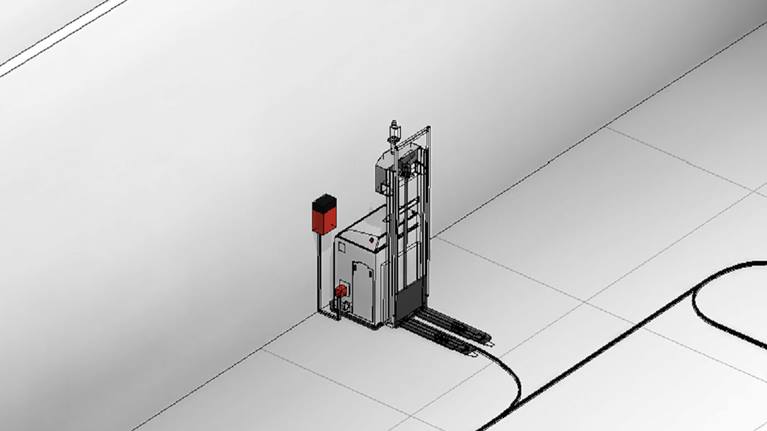

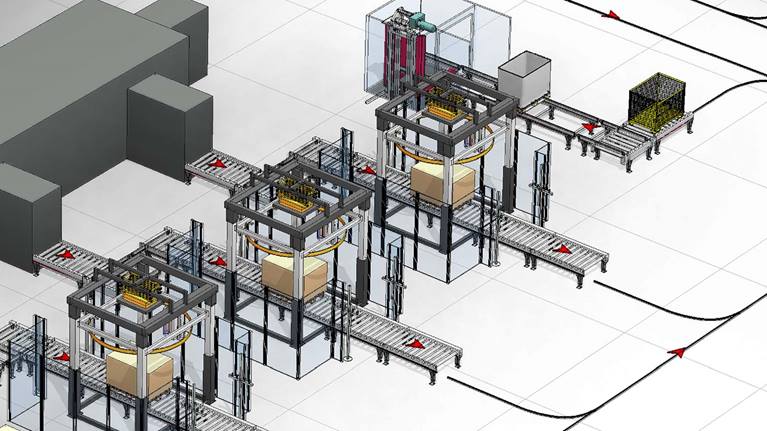

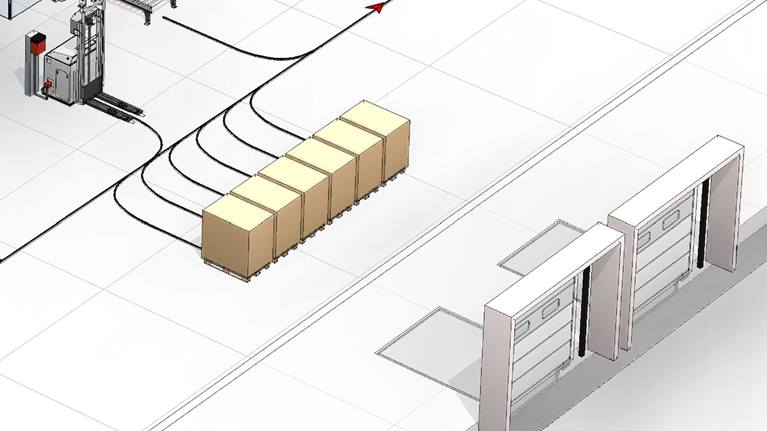

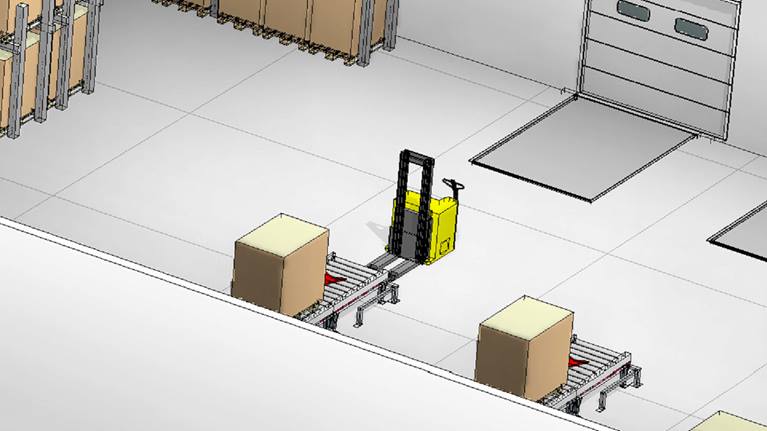

Working with our AGV suppliers, we find the best automated guided vehicle solutions for your enterprise, whether it is a standard forklift, a side forklift, a counterbalanced forklift, or a straddle AGV. We implement all types of vehicle, whether using a conveyor table or a platform vehicle. We can also integrate different types of AGV into the same layout.

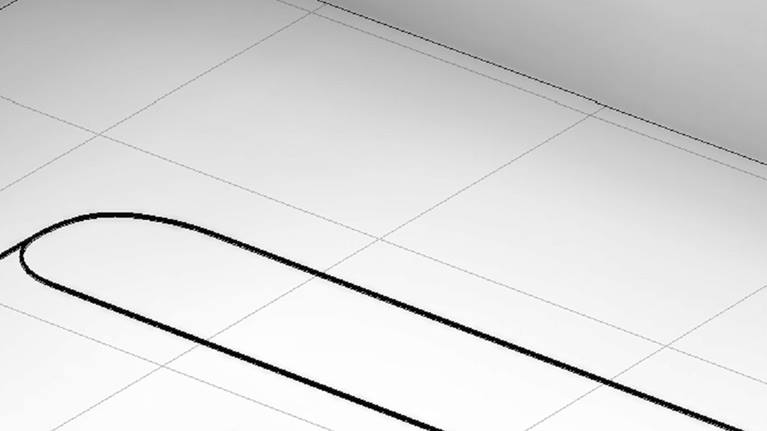

From many different types of AGV navigation, we select the most suitable for you. Natural navigation can completely avoid using any type of guidance, with vehicles simply using natural objects like walls and pillars instead.

For the highest precision, the best choice is laser navigation with reflectors or magnets in the floor.

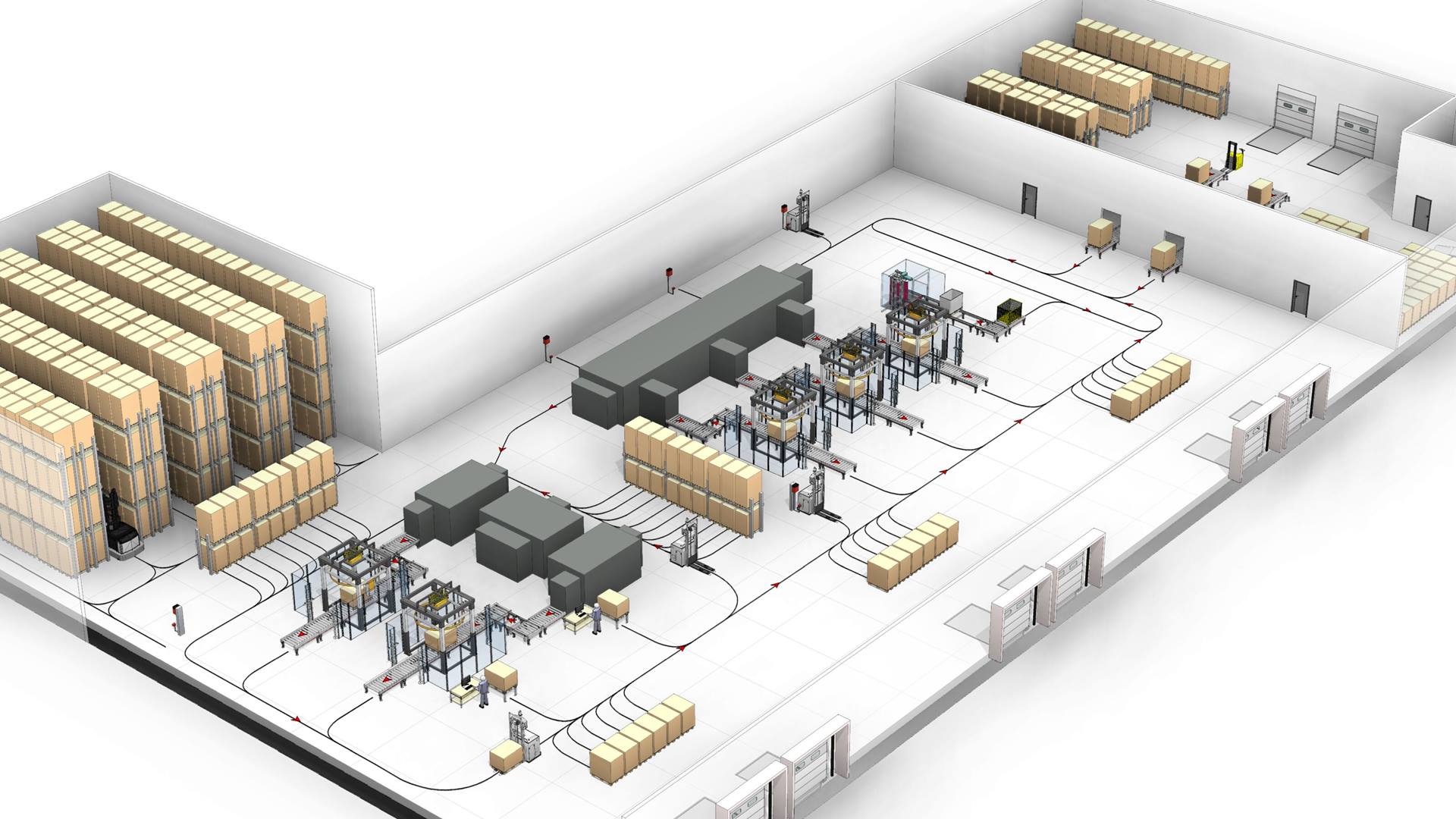

Solutions designs for Automated Guided Vehicles

The following factors are considered when designing an AGV solution:

- Material flow

- Size of layout

- Spatial requirements in the layout

- Vehicle speed

- Charging cycles

Automated guided vehicles (AGV): What are they?

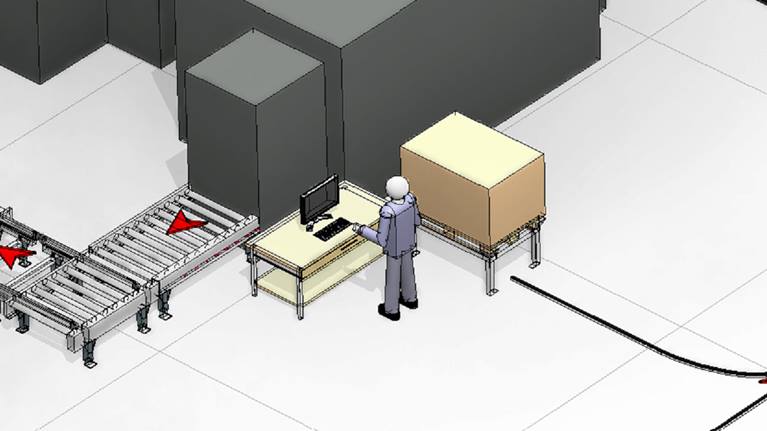

An automated guided vehicle (AGV) system transports various goods via computer-driven vehicles from a pick location to a drop location. The fleet manager distributes single transport orders to the vehicles. The shortest path to the destination is then calculated by the fleet manager. The AGV is a people-safe unit and is equipped with different safety components such as safety scanners, rubber bumpers and emergency stop buttons. Communication between vehicles and the fleet manager is done via Wi-Fi.

An AGV system comprises the following components:

- One or more vehicles with forks, platform or conveyor loading options to transport pallets, racks or containers.

- Layout on which the vehicles move, including pick and drop stations

- A fleet manager that distributes the transport orders to the vehicles and defines the route for vehicles

- Interface to doors, elevators, conveyors via I/O signals

- Interface to SynQ WCS or other host system that generates transport orders

An AGV system is an efficient and flexible transport solution with many advantages:

- Automated guided vehicles are widely used in several business sectors including: Industry, Pharma, Hospital, Food & Beverage, Retail, and E-Commerce

- Efficient solution for transports from A to B, with or without warehouse manager

- Ideal for mid-range to large distances up to medium material flows

- High redundancy when having several vehicles

- No fixed installations necessary in the layout

- Readily extendible at any time

- Guaranteed flow through times for material flow

- Reduction in staff

- High reliability and availability

- High return on investment (ROI), especially for 3-shift operation

Models: forklifts, counterbalanced forklifts, side forklifts, straddle, very narrow aisle, conveyor AGVs, platform AGVs

Speed: up to 1.7 m/s

Load weight: standard forklift up to 2,500 kg, customized AGVs up to 10,000 kg

Maximum rack height: 8 – 10 m

Charging strategies: automated charging “Opportunity Charging“, manual battery exchange

Batteries: lead - batteries, NiCd - batteries, Lithium-Ion-batteries

Application: Indoor

Temperature: +5°C – 35°C, higher or lower temperatures need to be clarified

Time from order to go-live: 6 - 10 months

Automated Guided Vehicles as mobile solution

We design your AGV system together with you. For this, the material flow, the size of the layout, the shift-model, and local conditions like slopes, bottlenecks, one-way-paths and a fire protection concept play an essential role.

We integrate our solution into your logistics landscape.

Together with Swisslog we created a distribution center that is perfectly equipped for future challenges. We can handle order throughput times of only 1 hour even with higher volumes

Learn more about AMAG’s use of AGVs in our customer case study.

Focus: Automated guided vehicles in the pharma industry

Automated guided vehicles can be used in many different applications, not least the pharmaceutical industry. High system availability, traceability of goods and shipments and «easy-to-clean» vehicles are all key requirements in the pharma sector.

To ensure GMP compliance, we design and realize AGV systems with special process requirements. Goods can be traced via barcodes or RFID. Quality control error handling ensures that any NOK goods are picked out.

AGV real time visualization with technology partner

Our longstanding partnership with technology partner Kollmorgen is key to our success in the AGV sector. Kollmorgen offers guaranteed spare parts availability for all the most important components as well as useful tools for diagnosis and analysis. We can quickly detect any irregularities in the system to ensure optimized operation.

Cway realtime visualization gives you complete control over the system at any time; you can see the position and the status of every vehicle. An event log records all transports and load exchanges. With CWay you have the option to create different users and user groups and to grant access to the system according to authority level.