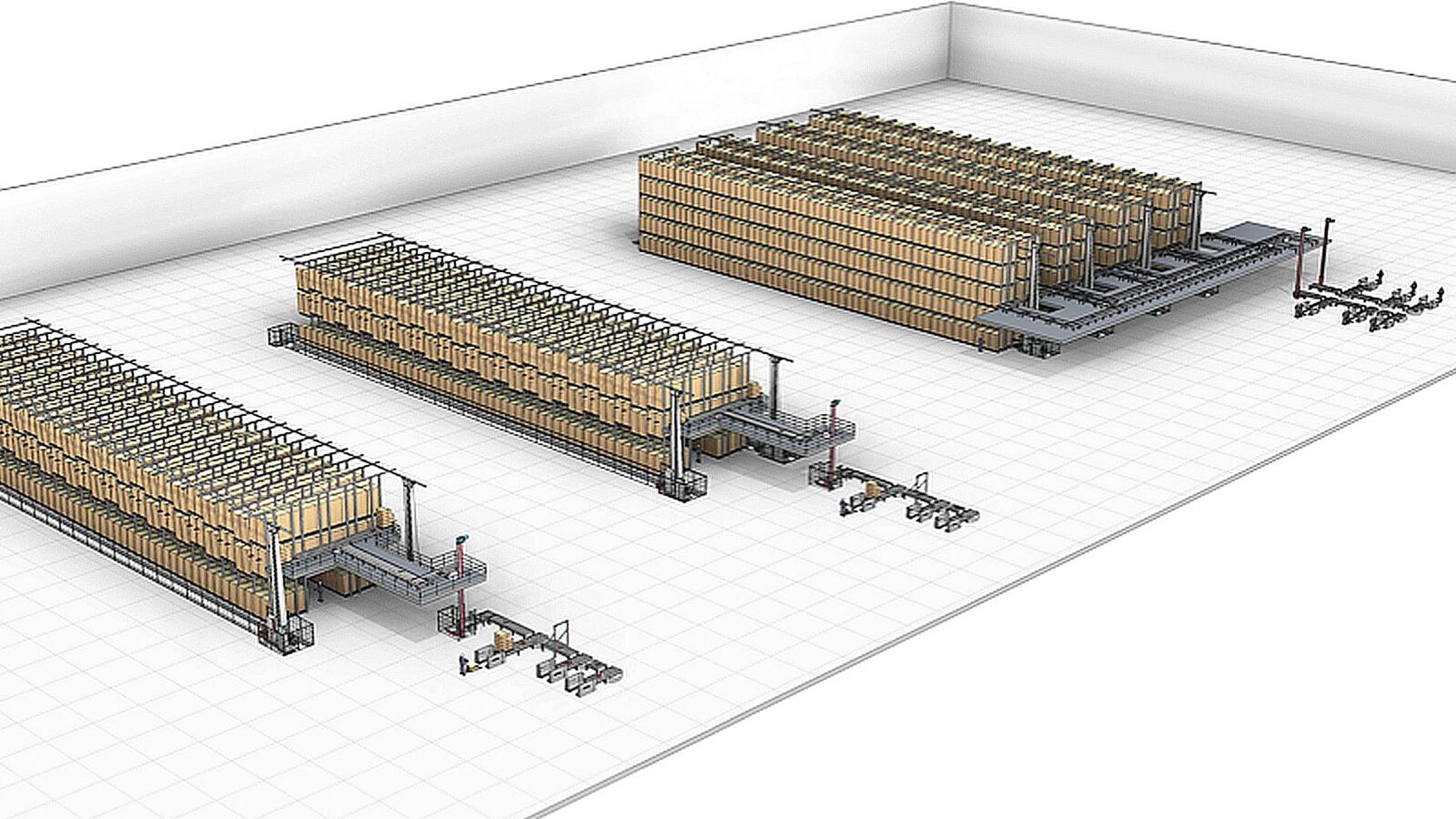

Rewe Dortmund, Germany: Future logistics for fresh produce storage

The retail company Rewe Dortmund realized one of the largest projects in its company history – the construction of a new logistics center for fresh produce, such as dairy products, fruit and vegetables. Automated and semi-automated pallet technology from Swisslog works in combination with modern software to streamline material flows.

Centralization strategy

The new fresh produce warehouse is the result of a centralization strategy in which Rewe Dortmund combines four warehouses at one location. A building complex covering some 45,000 square meters was constructed in Dortmund-Westfalenhütte. Andreas Schmidt, CEO of Rewe Dortmund, says: "Our new logistics center saves us about one million transport kilometers per year and reduces energy consumption by about 30 percent."

Modern pallet technology & software

The heart of the new Rewe logistics, which operates at 6°C and 12°C, is an automated, four-aisle pallet high-bay warehouse for dairy products – featuring 4,320 storage locations and four Vectura stacker cranes. Two semi-automated flow storage blocks with a total of 2,650 pallet spaces, also equipped with four Vectura stacker cranes, provide space for fruit and vegetables. ProMove conveyor technology ensures the inflow and outflow of goods.

Swisslog implemented a material flow computer with SPOC visualization tool for the overall control.

The new construction is designed as a fresh produce hub, which considerably increases the efficiency of our logistics.