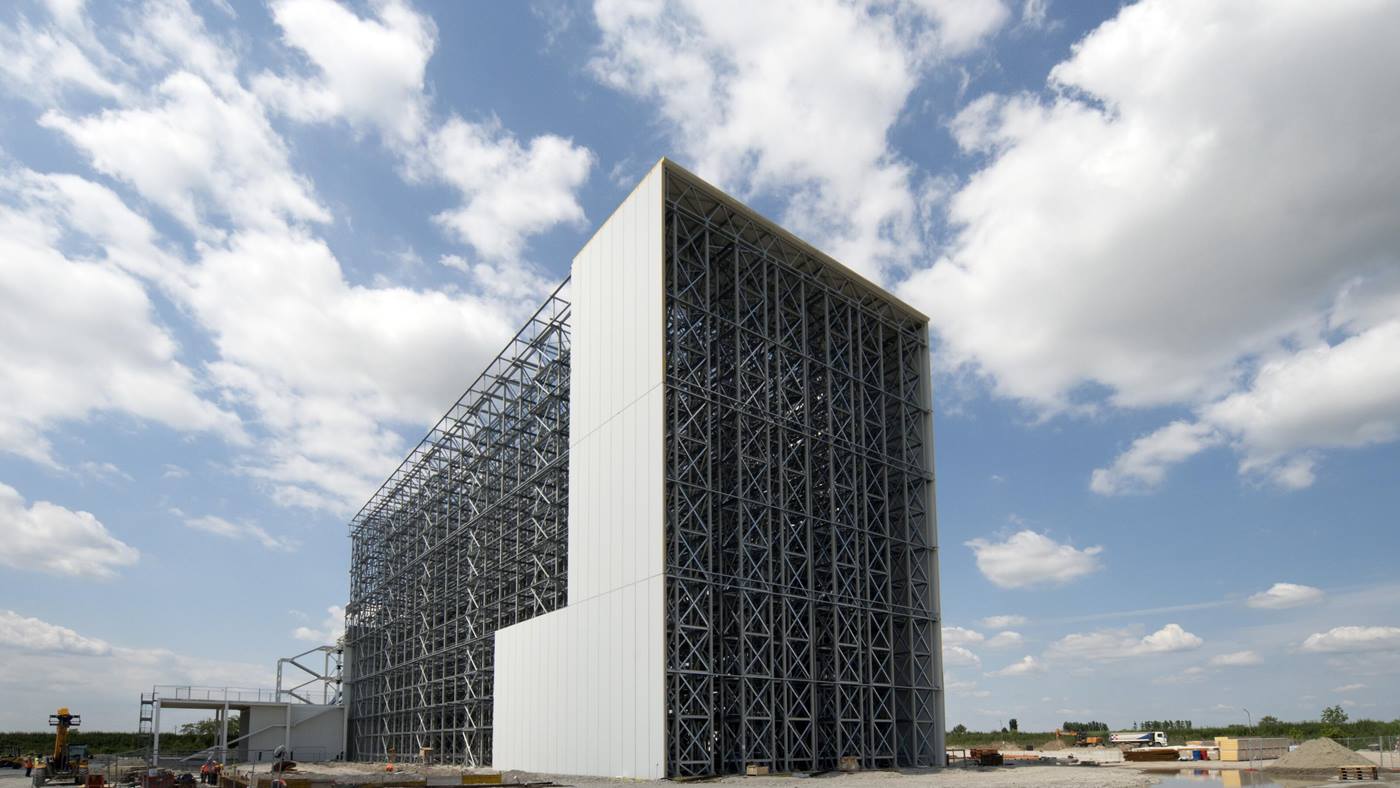

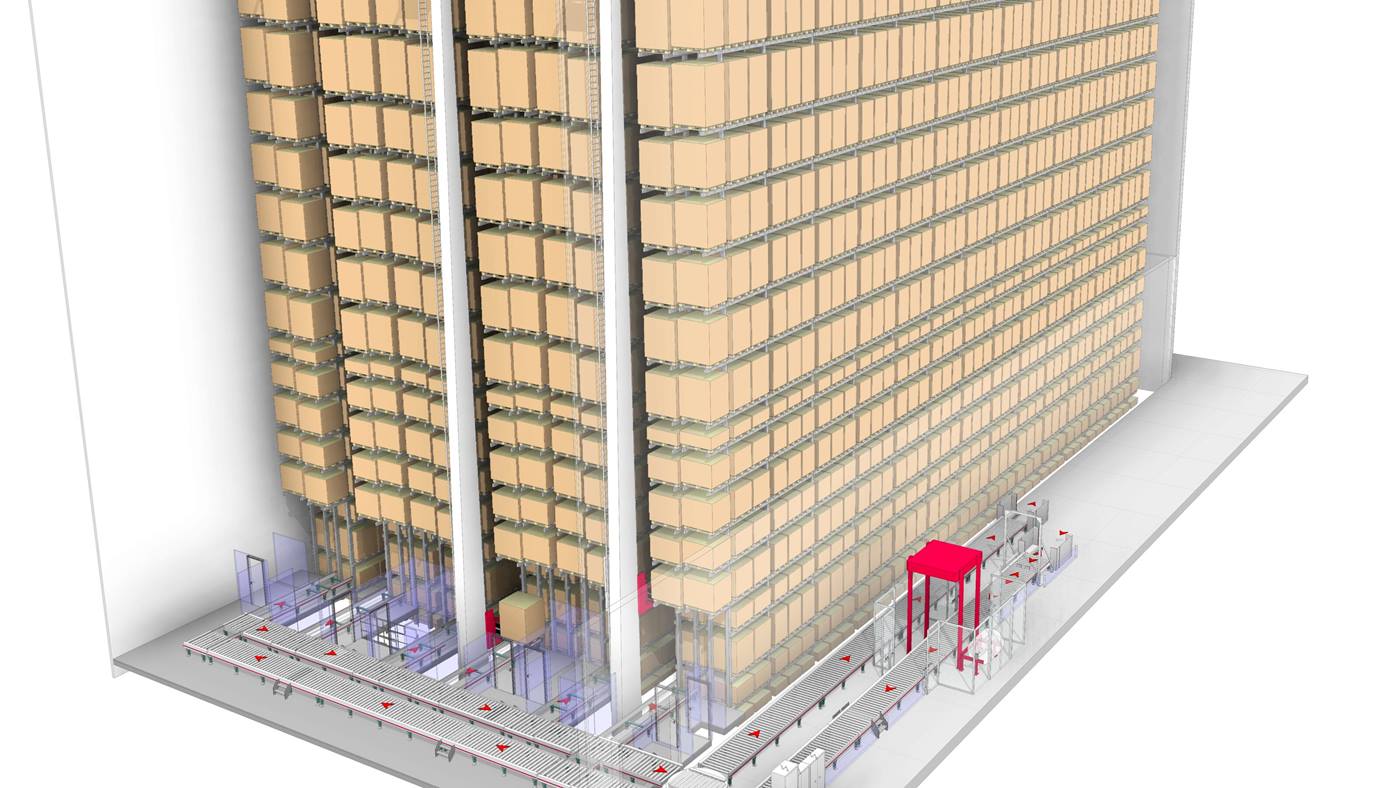

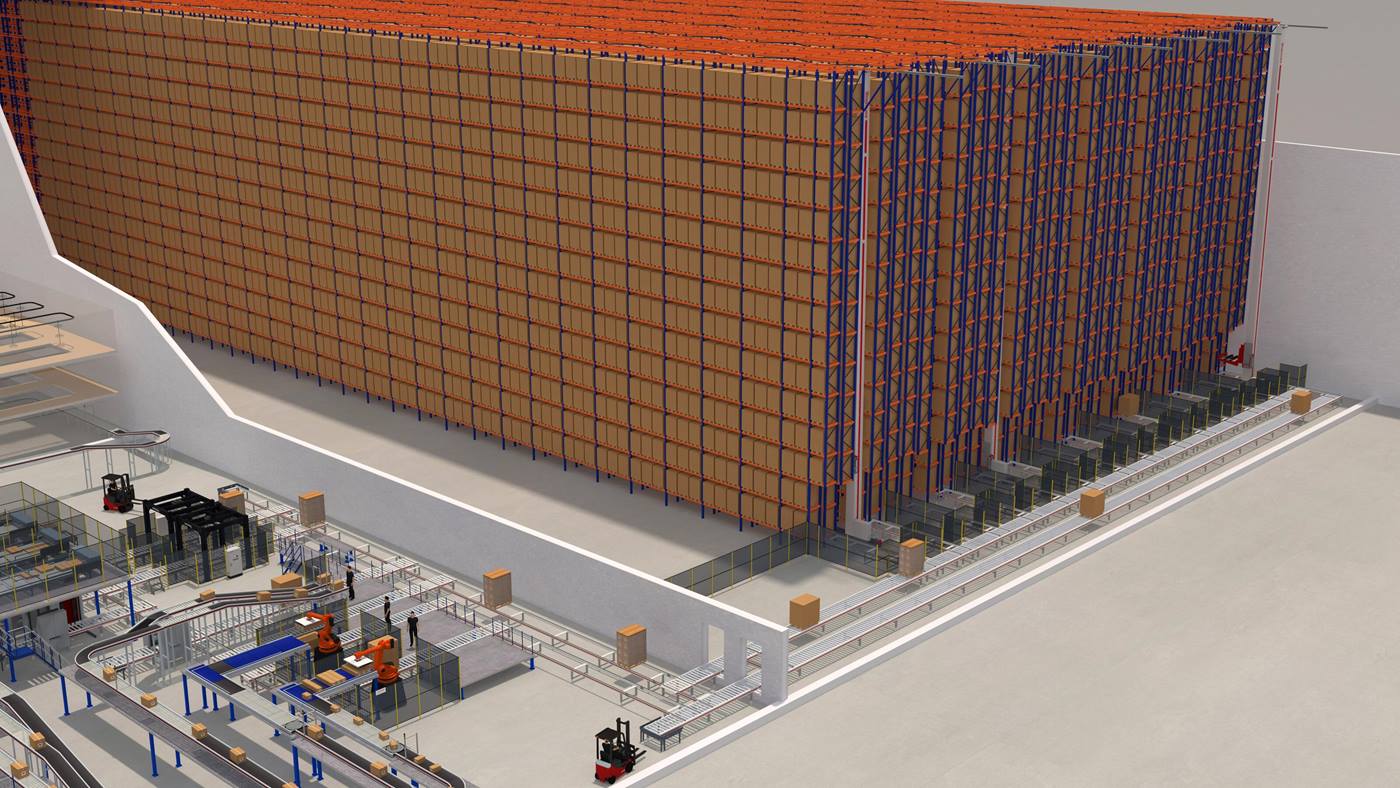

Automated high bay warehouse HBW for heavy and medium loads

The automated high bay warehouse is the all-rounder for heavy and medium loads. Controlled by modern software, the storage and retrieval process takes place completely independently – making it highly dynamic and very safe. Its performance extends to round-the-clock operation.