Swisslog Partners with Peapod Digital Labs to deploy micro-fulfillment technology

The pilot launches as Ahold Delhaize USA companies continue to expand e-commerce fulfillment capabilities as part of readying an omnichannel supply chain and supporting their U.S. brands as they pursue their ambitions of becoming the leading omnichannel grocery retailer in their markets.

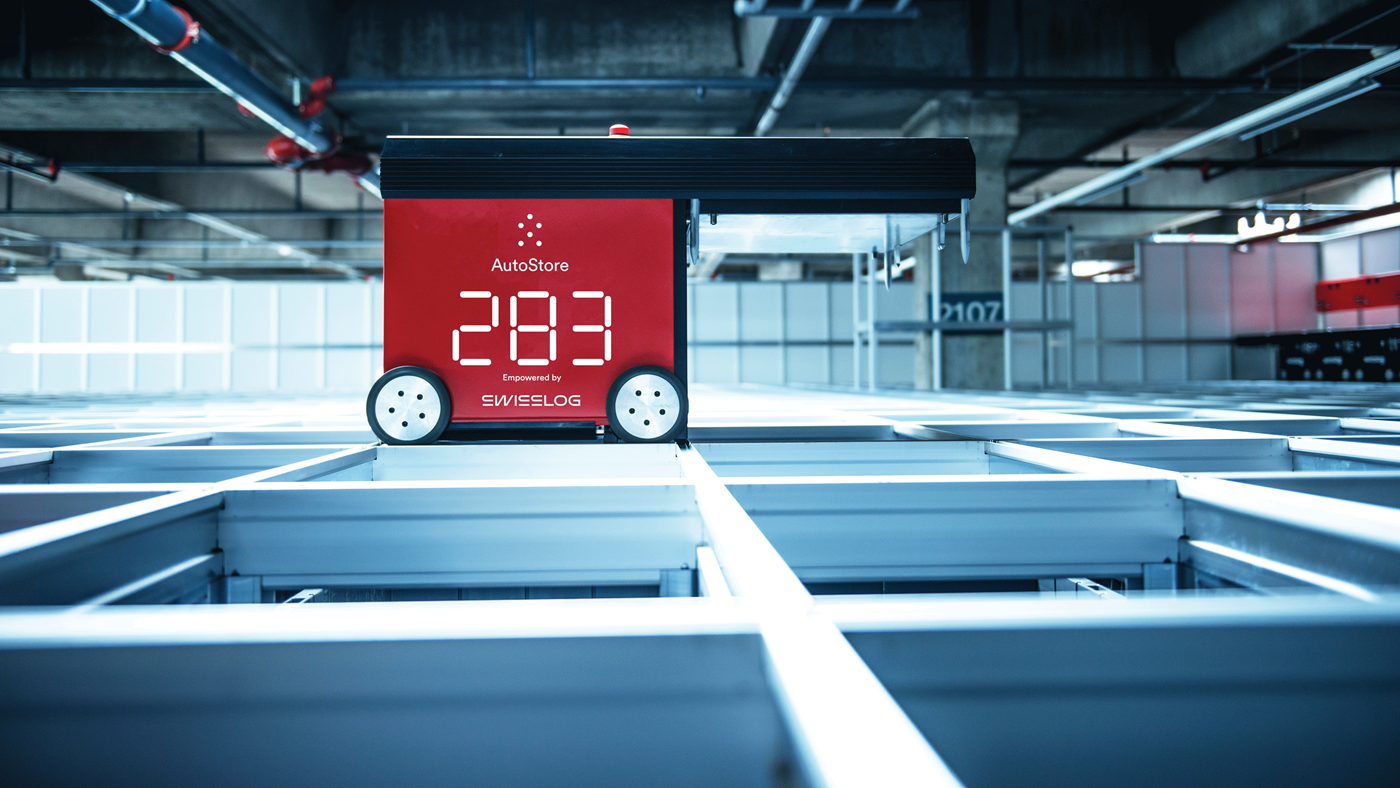

We could not be more pleased to partner with Peapod Digital Labs and The GIANT Company. For the pilot, we’ve combined AutoStore with our Swisslog SynQ software platform, which has grown to have a very robust set of standard features geared specifically to e-grocery fulfillment. Applying the advantages of the AutoStore grid storage density and goods-to-person productivity gains in tandem with Peapod Digital Labs’ picking system creates a flexible solution ideal for streamlining grocery e-commerce order fulfillment.

JJ Fleeman, president of Peapod Digital Labs and chief ecommerce officer, said all Ahold Delhaize USA companies have seen a tremendous increase in online sales growth over the past year.

“As we think about shifting consumer expectations and the future of omnichannel shopping, we know we must have the right infrastructure in place for both pick-up and delivery,” he said. “We’re excited to kick off this pilot with The GIANT Company and Swisslog as we continue to build out ecommerce fulfillment capabilities, including micro-fulfillment, which we believe will be key in supporting continued omnichannel growth.”

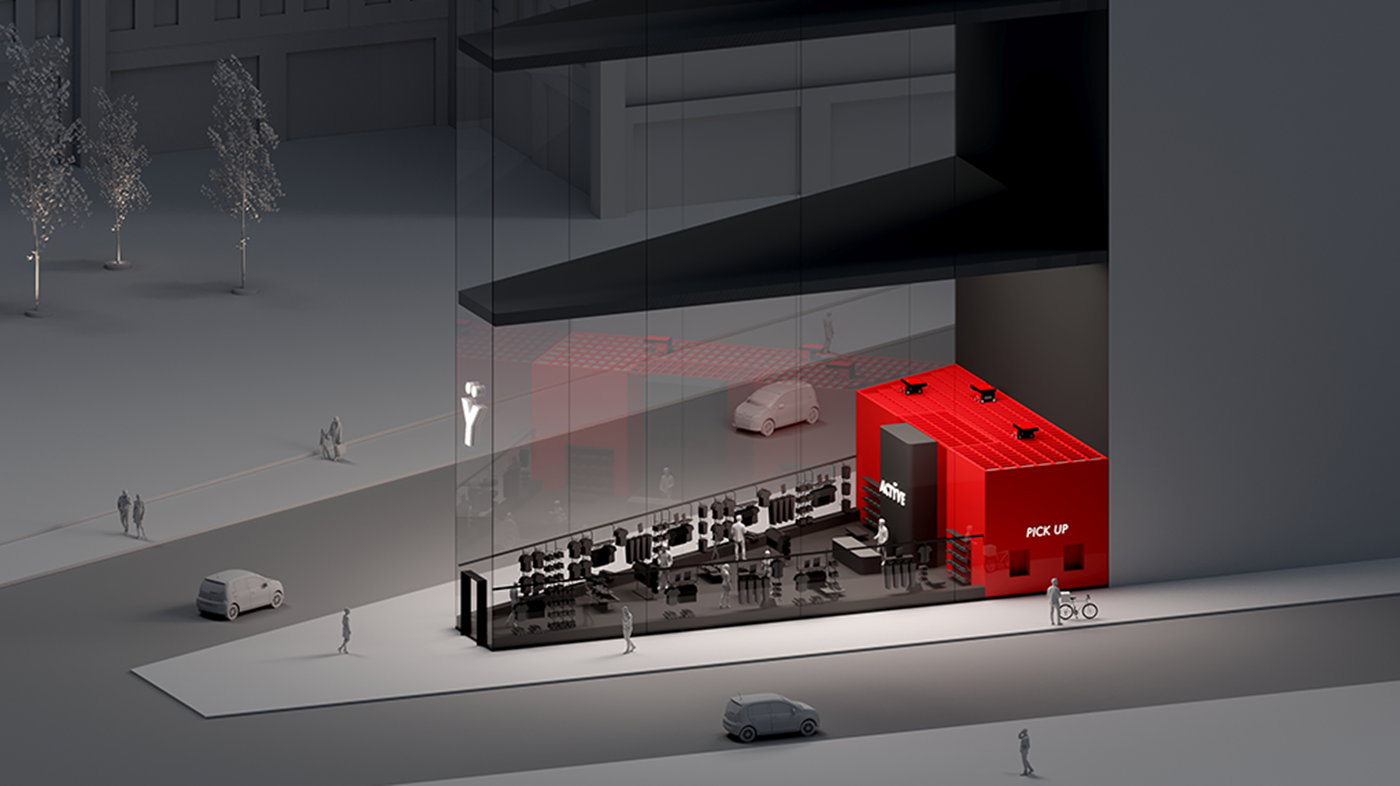

Moving storage and fulfillment closer to consumers while maintaining the agility to quickly relocate those functions as market demand shifts or supply chain needs change is an essential characteristic of the supply chain of the future. And with Swisslog’s help, companies like Peapod Digital Labs and The GIANT Company are leading the way in showing the value micro-fulfillment technology can bring to e-grocery.

Discover how automated micro-fulfillment centers fit within your supply chain strategy? Visit our micro-fulfillment center webpage.

While they can be used in a number of market segments and industries, micro-fulfillment centers have gained the spotlight as a result of the accelerated demand in e-grocery fulfillment. Micro-fulfillment has shown to be an ideal solution for streamlining e-grocery fulfillment.

Part of what the company refers to as an e-commerce fulfillment center (EFC), the pilot leverages Swisslog’s warehouse automation solutions, including AutoStore technology empowered by Swisslog’s SynQ software, as well as Peapod Digital Labs’ proprietary manual picking capabilities.