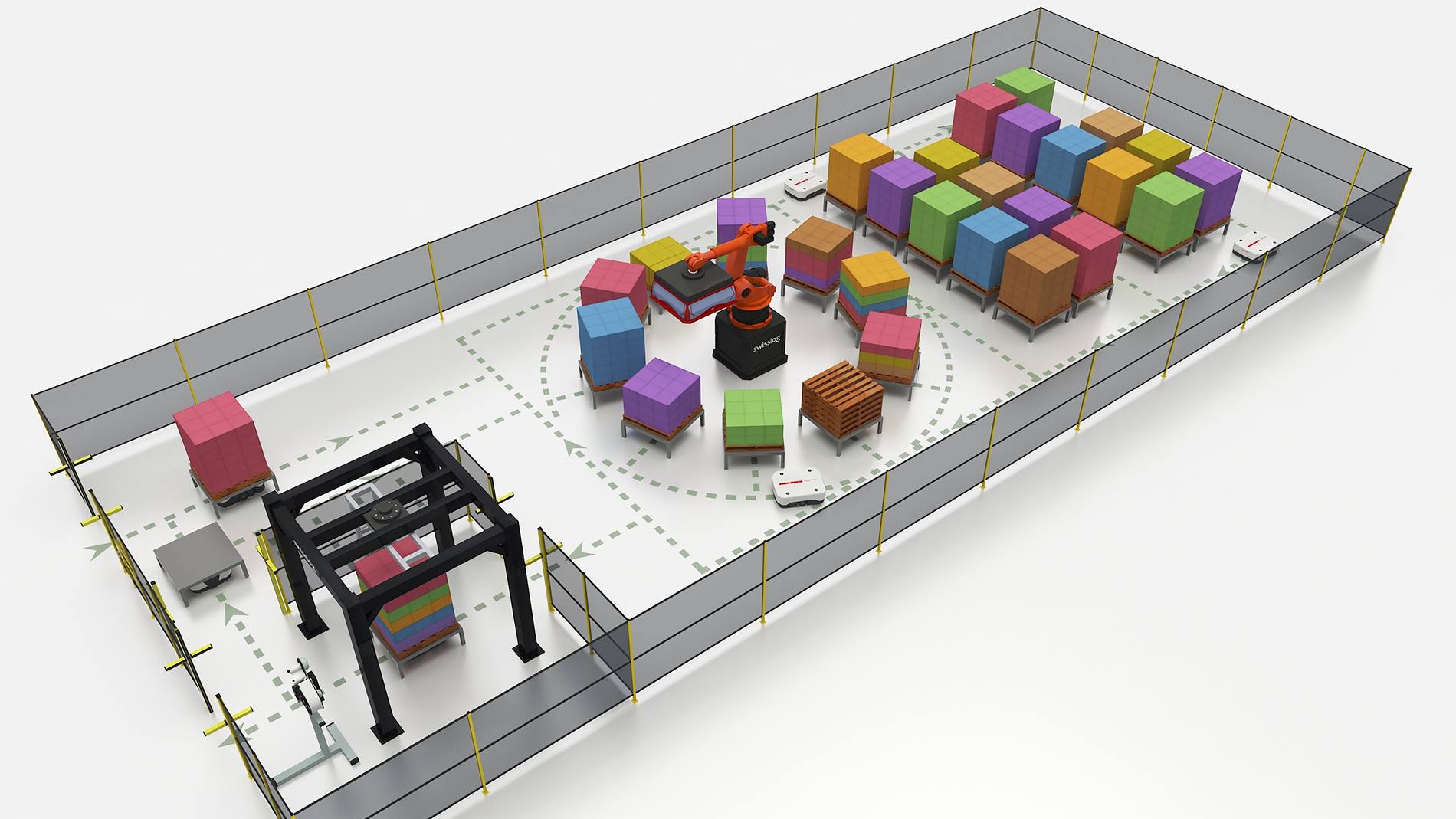

The new CarryStar - A fully automated layer and stack picking solution

Developed here in Australia by Swisslog's Senior Consultant Paul Stringleman, CarryStar (launched July 2018) is a new automated solution, that utilises fixed and mobile robot technology, to solve a common warehouse problem in a new and transformative way.

Named CarryStar as the word “Carry” refers to the team of autonomous mobile robots (AMRs) that transport pallet loads of goods around the inside of the system, while the word “Star” refers to order picking robot(s) that are in a star configuration.