TTI, USA: Electronics distributor adapts to changing market

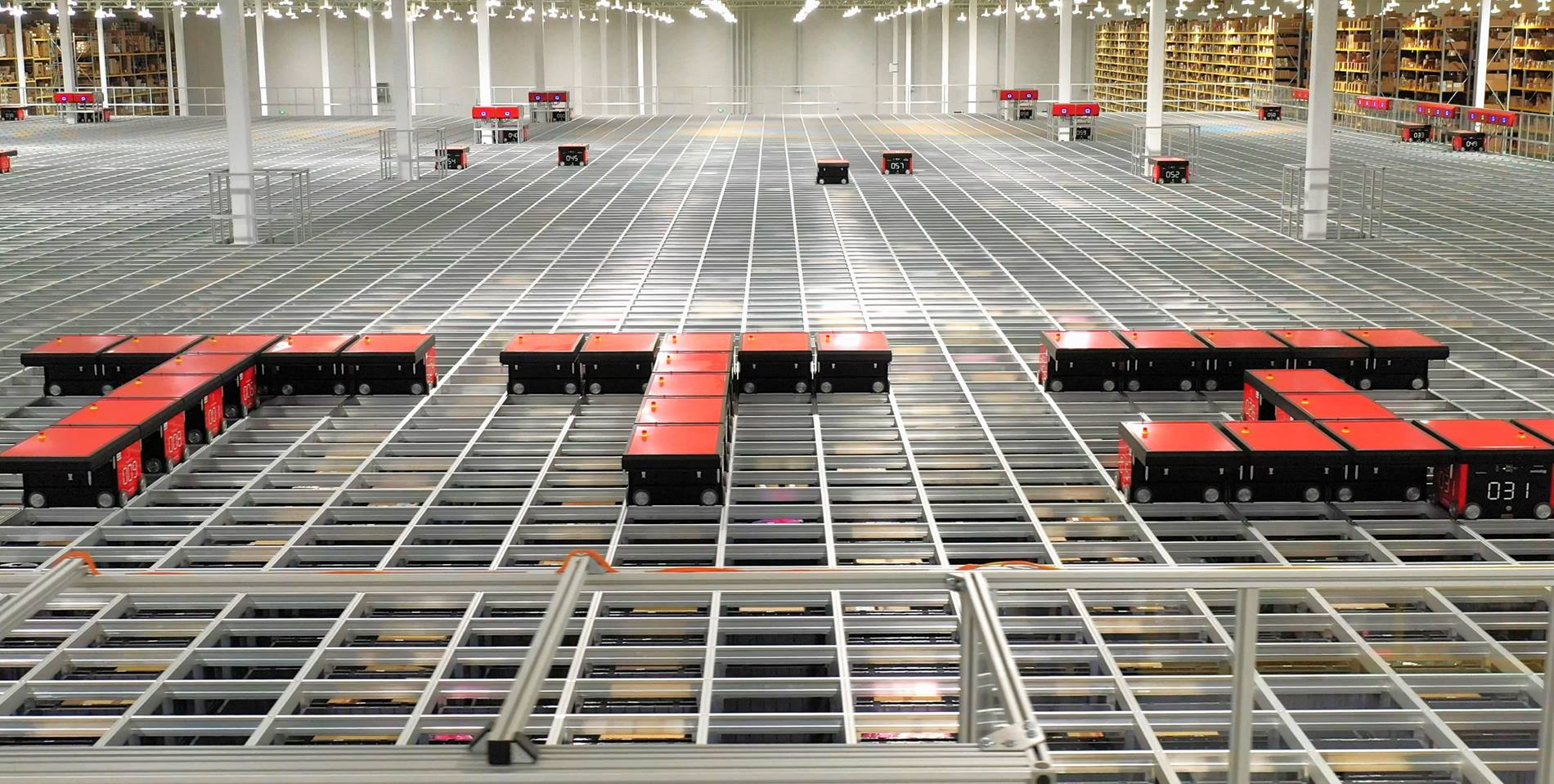

TTI implemented an AutoStore system with Swisslog’s SynQ software that has increased storage capacity, streamlined processes and will enable continued growth without compromising the customer experience.

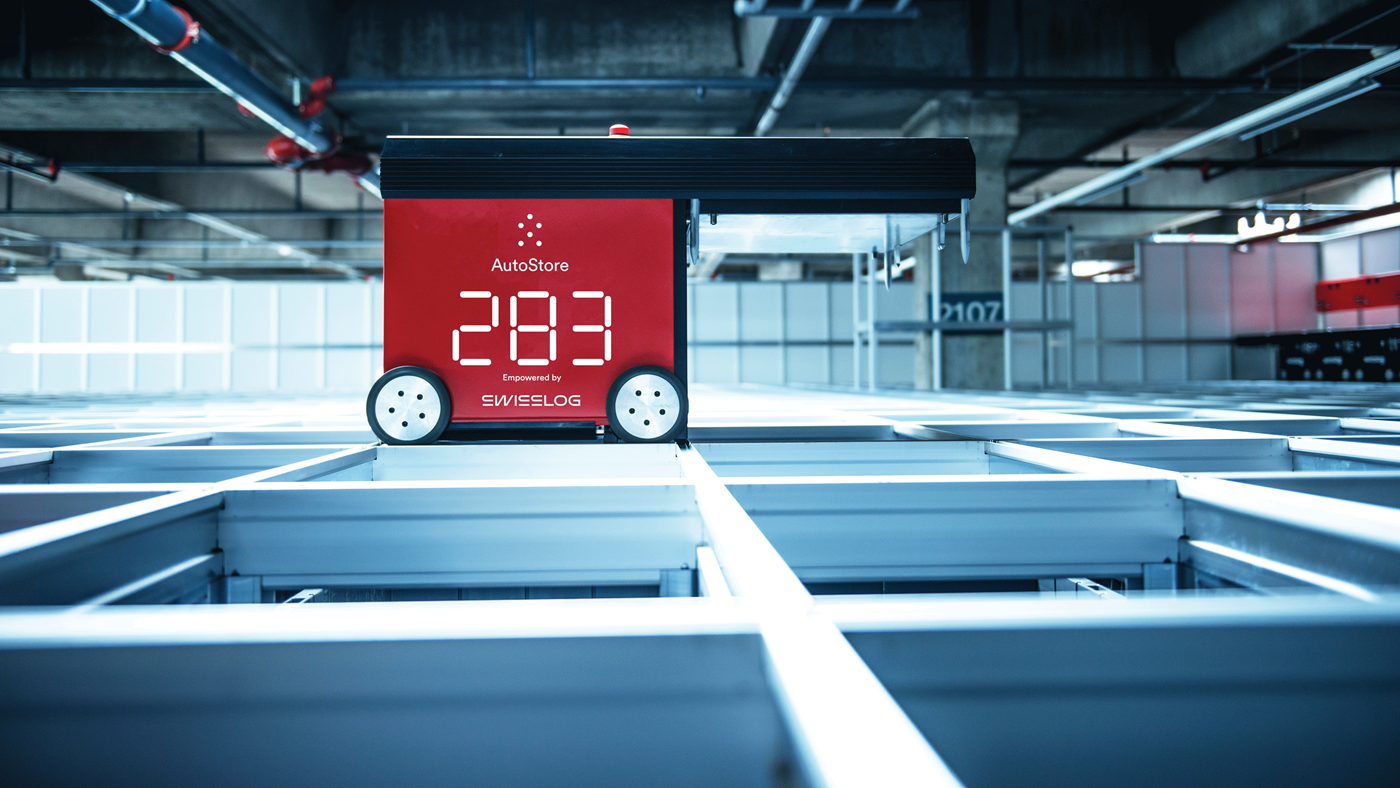

Based on a positive experience inside its family of companies, TTI chose Swisslog to integrate the AutoStore system. Swisslog is the leading AutoStore integrator with deep experience and established processes for configuring and implementing AutoStore systems.

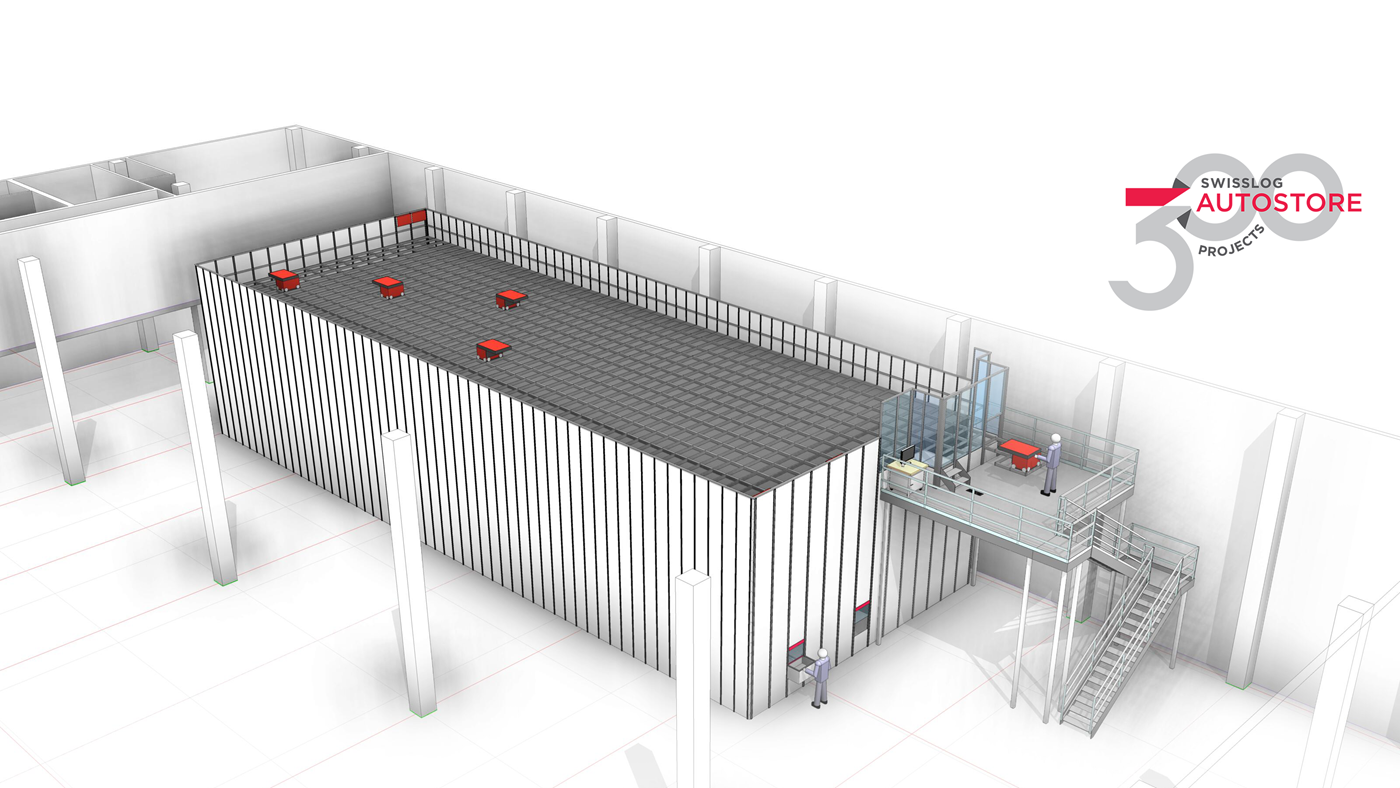

The AutoStore is configured to support TTI’s inventory and customer order profiles with 135,000 bins, which can each be subdivided to support multiple SKUs in the same bin, 36 picking ports and 8 put-away ports.

The AutoStore is configured to support TTI’s inventory and customer order profiles with 135,000 bins, which can each be subdivided to support multiple SKUs in the same bin, 36 picking ports and 8 put-away ports.

Swisslog SynQ Software

The Right Solution from the Right Partner

Swisslog offered robust software for the AutoStore system that provides users more control over how robots retrieve bins, and in how orders are allocated, prioritized, grouped and released. The software has been tested at up to eight million SKUs – and is supporting more than that in some applications – so there was no question that it could handle the high SKU counts of this application.

Our operators have found the SynQ software easy to use and intuitive. We’ve already seen a 50% improvement in our picking speeds compared to our existing goods-to-person system and we plan to improve on that. With AutoStore and SynQ, we can get stock from our suppliers to our customers faster and more efficiently than we could before.