B. Braun Spain: Automated plant doubles storage capacity

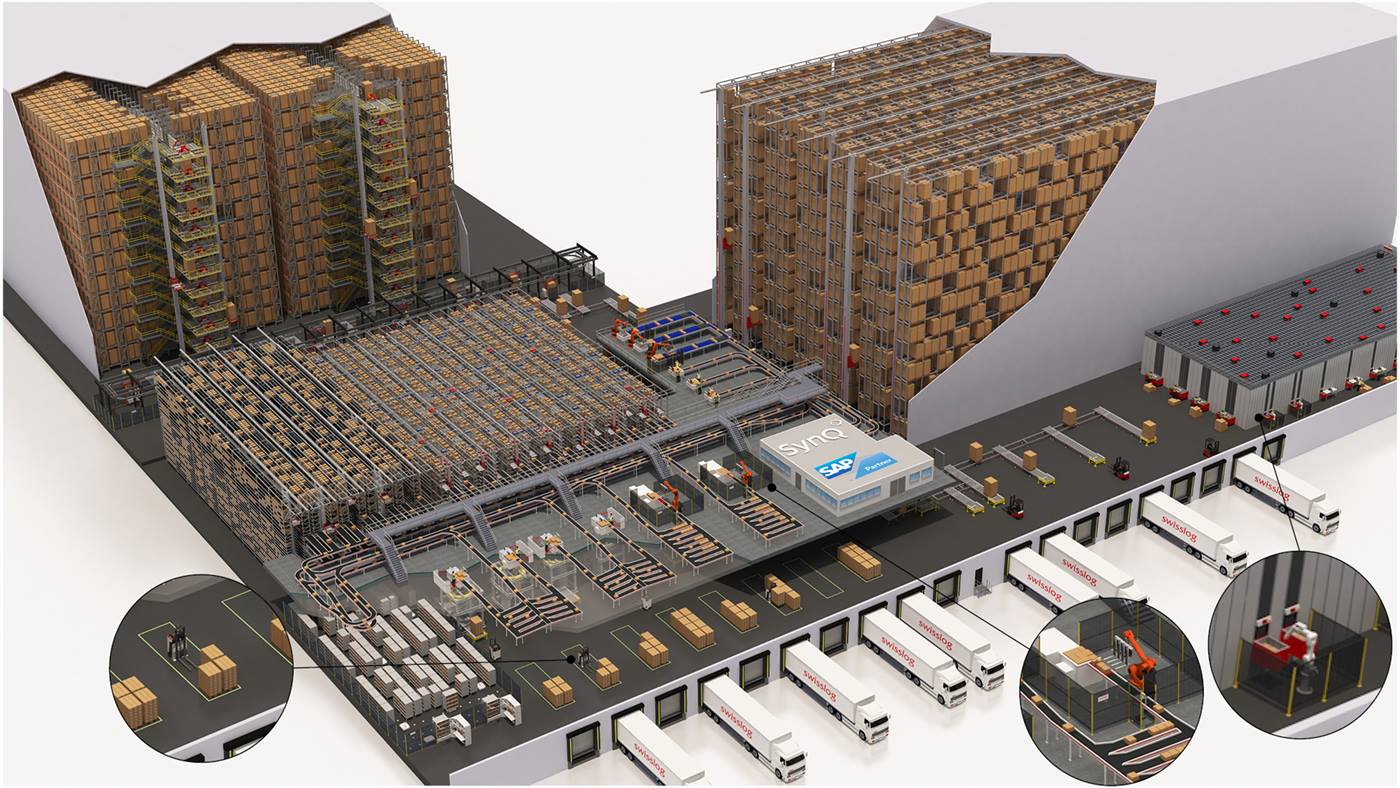

B. Braun's suture plant has undergone a major transformation that has resulted in the complete automation of all production and warehousing processes, comprising of 65 robots. This transition in logistics was made possible thanks to B. Braun’s collaboration with Swisslog.

A tailor-made and more efficient solution

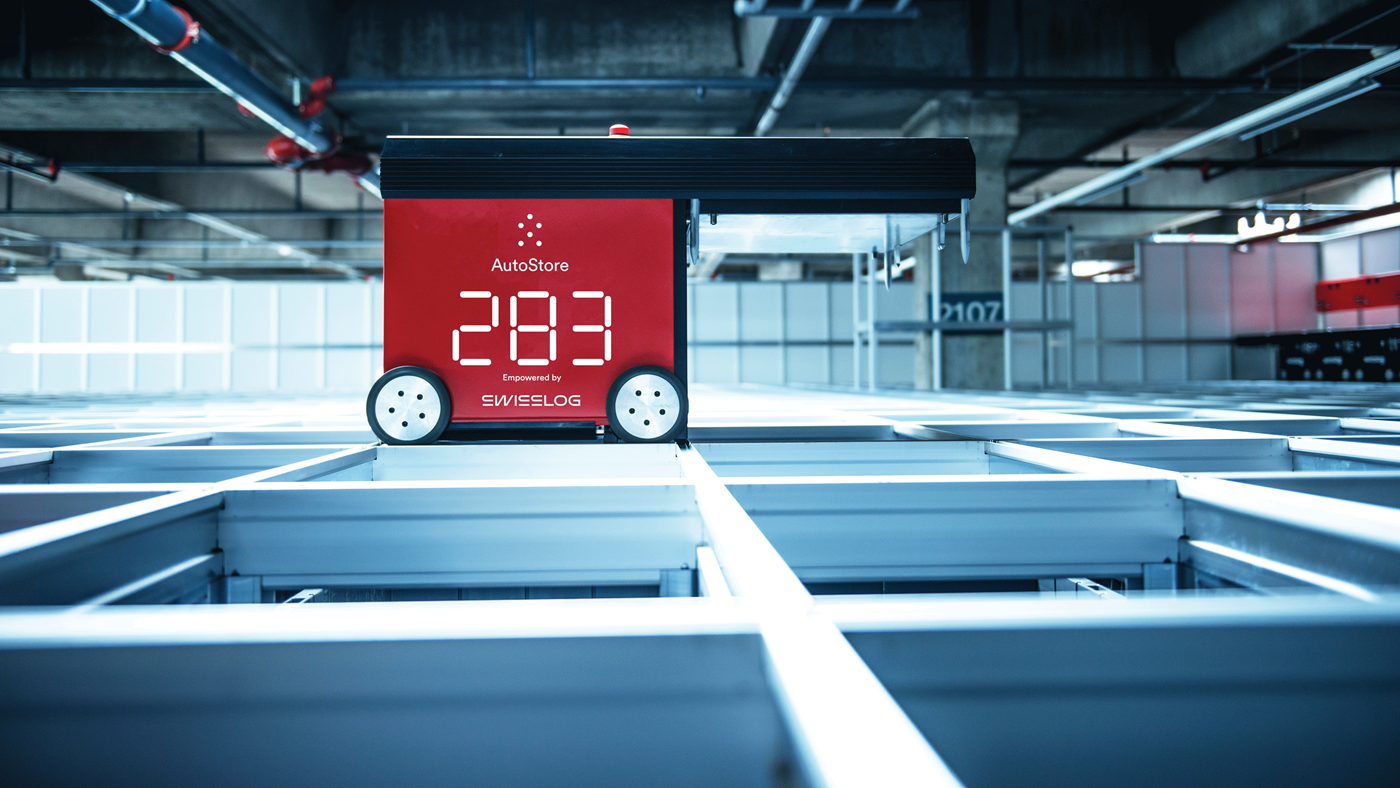

Thanks to the automation of the warehouse with the AutoStore system, B. Braun Spain has been able to double the storage capacity of the plant.

This is synonymous with greater efficiency in carrying out its mission to care for and protect people's health, as well as to meet the growing demand for suture supplies in recent years.

Adaptation to existing spaces

The technological transformation resulting from this automation with Swisslog's AutoStore solution was also made possible by connecting the production plant to the warehouse.

In this way, the sutures, once placed in the boxes that the end customer receives, are transported directly to the warehouse using a system that allows them to be placed in bins (30,000 in total) and then located and handled by robots.

The extensive automation implemented allows our logistics operations to be more flexible and adapted to the current needs of our healthcare market. This modern warehousing solution is, for example, easily scalable to more capacity in the future.