Robot, or Not?

10 August 2016

James Sharples, Managing Director of Swisslog UK, examines the future of robotics in intralogistics.

If you asked the average man or woman on the street to imagine a robot and describe it, their vision would most likely be similar to C-3PO from Star Wars or Brian from the comparison site advertising campaign. It would probably be human in form and have some sort of personality. This demonstrates the power of the screen, whether big or small.

The reality is that the robots that we have experienced until now are more likely to have been just a box of electronics with some mechanical activation – such as an automatic door opener or a robotic lawn mower.

Personal robots

However, more sophisticated robots are now set to enter our lives. We have all read, for example, about the self-driving cars that are being extensively tested around the world. Recognising our human sensibilities, many of the collaborative robots (or cobots) being trialled today actually have human forms. Take, for example, ‘Baxter’, the cobot from Rethink Robotics, which has a screen-based ‘face’ and two arms.

In Japan – the most elderly nation in the world, with 20% of the population aged 65 or over – scientists are perfecting humanoid robots that can help the elderly by getting meals or turning off lights. Unlike a human carer who might call in twice a day for 15 minutes, these carer robots (or carebots) are present for their patient 24/7.

An emotional – rather than functional – robot named ‘Pepper’ is being sold in Japan at a cost of just over £1,000; it tends to its owner’s emotional needs by learning about them and having conversations with them, using an ‘emotional engine’. There are also robot ‘pets’ designed to help improve their owners’ wellbeing.

According to a report by Merrill Lynch, the global personal robot market – including carebots – could reach $17.4 billion by 2020.

The rise of the cobot

We have seen many examples of robots in the logistics industry – from automated guided vehicles (AGVs) to robots picking a range of products. Although robots have been around for some time in the distribution industry, so far they have tended to be used to replace humans in various specific roles rather than in collaborative applications.

This is where change is now happening. Think about an order picker who has as his work partner a multi-axis robot, which has a myriad of tools (think ‘hands’) at its disposal. The robot could help the order picker with the mundane, repetitive tasks whilst leaving the human to cover tricky items and to validate the whole operation. If one considers the pharmaceutical industry, for example, the order picker could be a qualified pharmacist with overall control whilst the robot does much of the work.

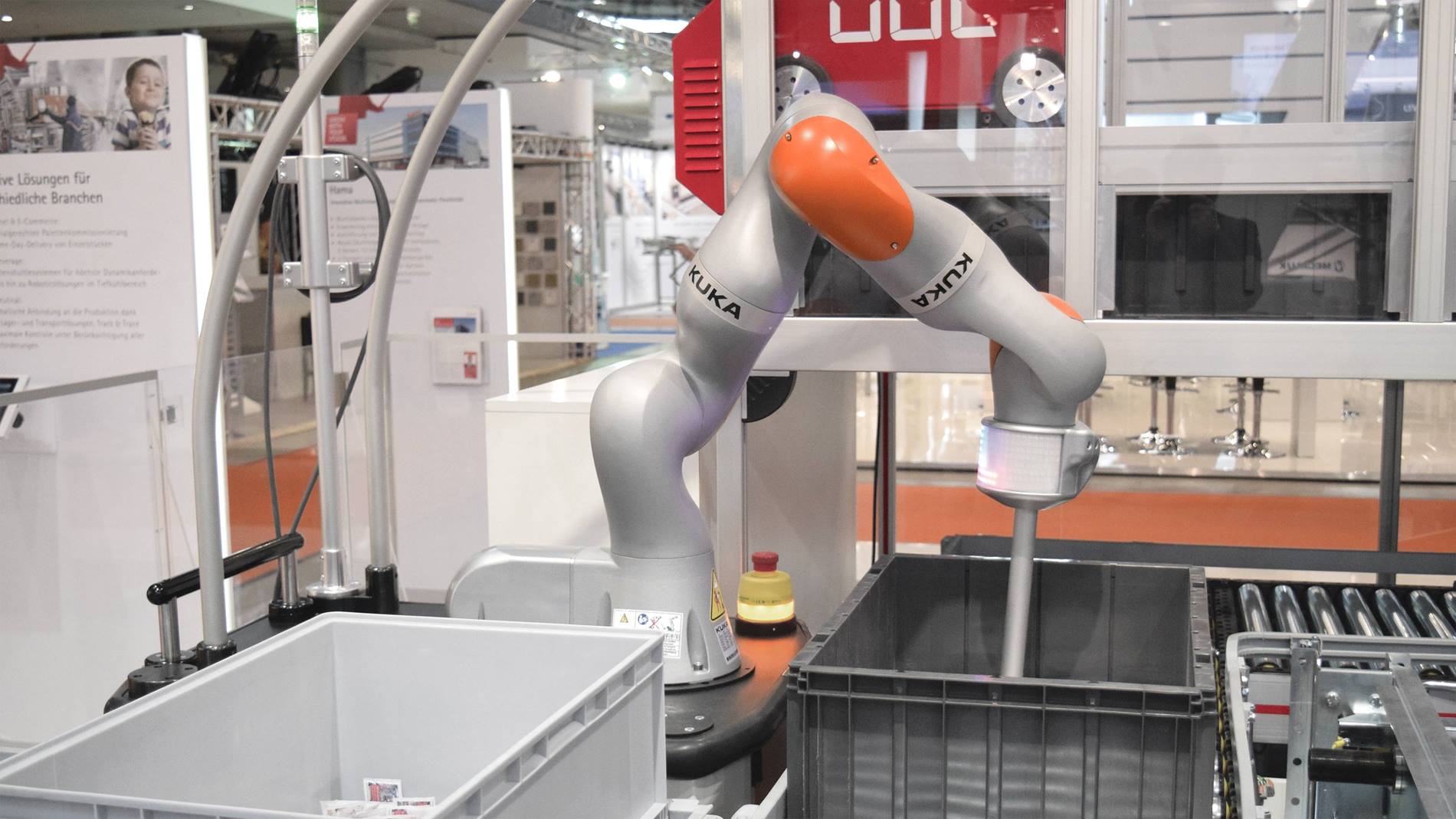

This is the concept behind Automated Item Pick (AIP), Swisslog’s human-robot picking solution, which was recently awarded the 2016 INDUSTRIEPREIS in the category ‘Intralogistics & Production Management’. At the heart of AIP is a lightweight KUKA robot that is equipped with state-of-the-art sensor technology and a 7-axis gripper. A distinctive feature of this solution is that the order bins at the pick station are served by a human hand and the robot’s grippers at the same time, without the need for a safety barrier between man and machine.

The Western world today is facing reductions in the available workforce due to falling population levels. In this scenario, robots will increasingly be seen as the solution to the more labour-intensive operations in the modern warehouse. Robotic automation may help to plug the labour hole by replacing workers or, more likely, by supporting them to increase productivity.

“Recognising our human sensibilities, many of the collaborative robots (or cobots) being trialled today actually have human forms.”