Lineage Logistics, USA

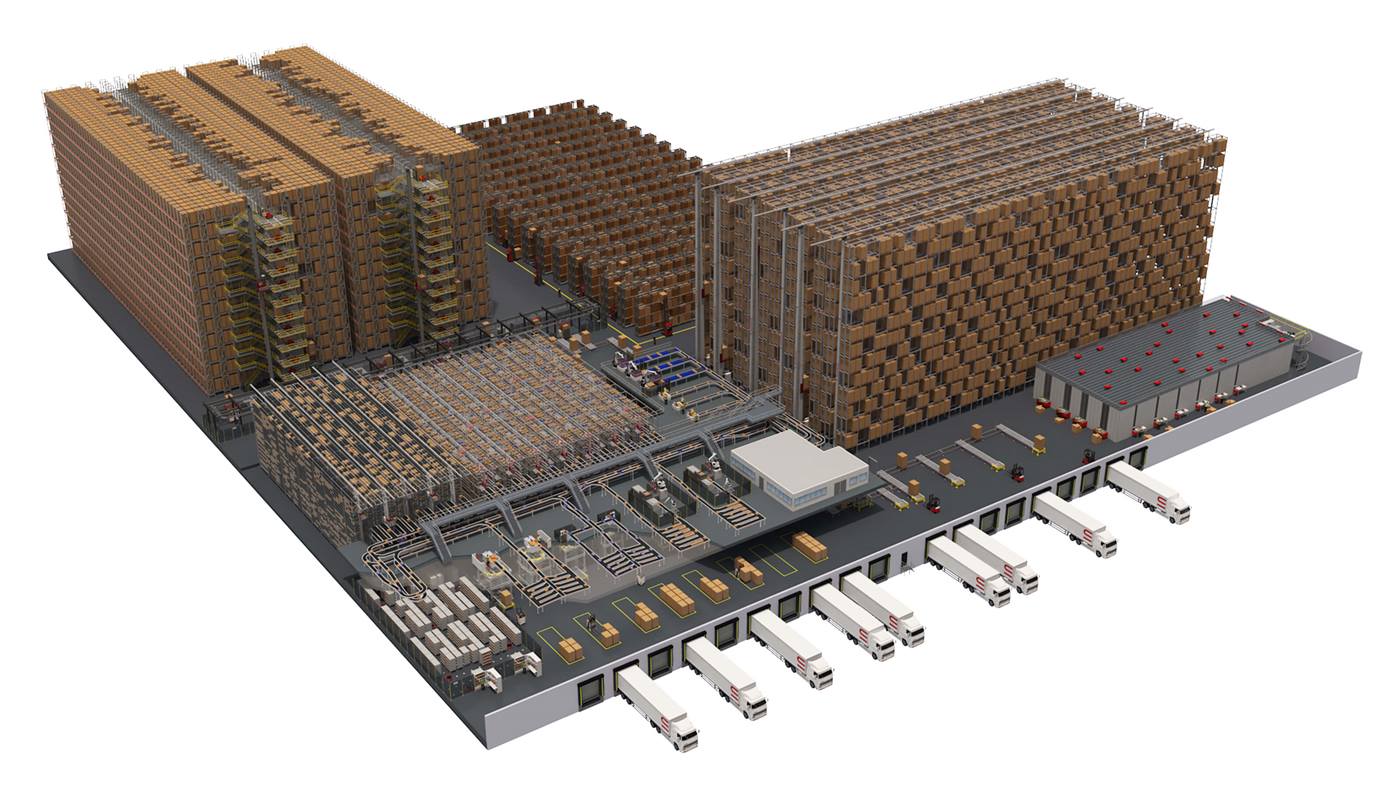

At the heart of the Lineage facility is Swisslog's PowerStore automated storage and retrieval system. The compact, high density pallet shuttle system is capable of meeting high throughput requirements while minimizing worker exposure to the harsh conditions in the cold.

PowerStore drives high throughputs in next generation cold storage facility

Lineage Logistics, a global leader in cold storage, is not a company to wait for change to happen. They are committed to delivering increased value to customers through innovation driven by data analytics and enabled by market-leading automation.

The latest example is the 96,000-square-foot expansion of the company’s Sunnyvale, Texas, cold storage facility. The expansion, powered by Swisslog’s PowerStore automated storage and retrieval system, was Lineage’s first fully automated cold storage facility in North America and was designed to serve as a template for the company’s next generation cold storage warehouses.

Automating Cold Storage Distribution

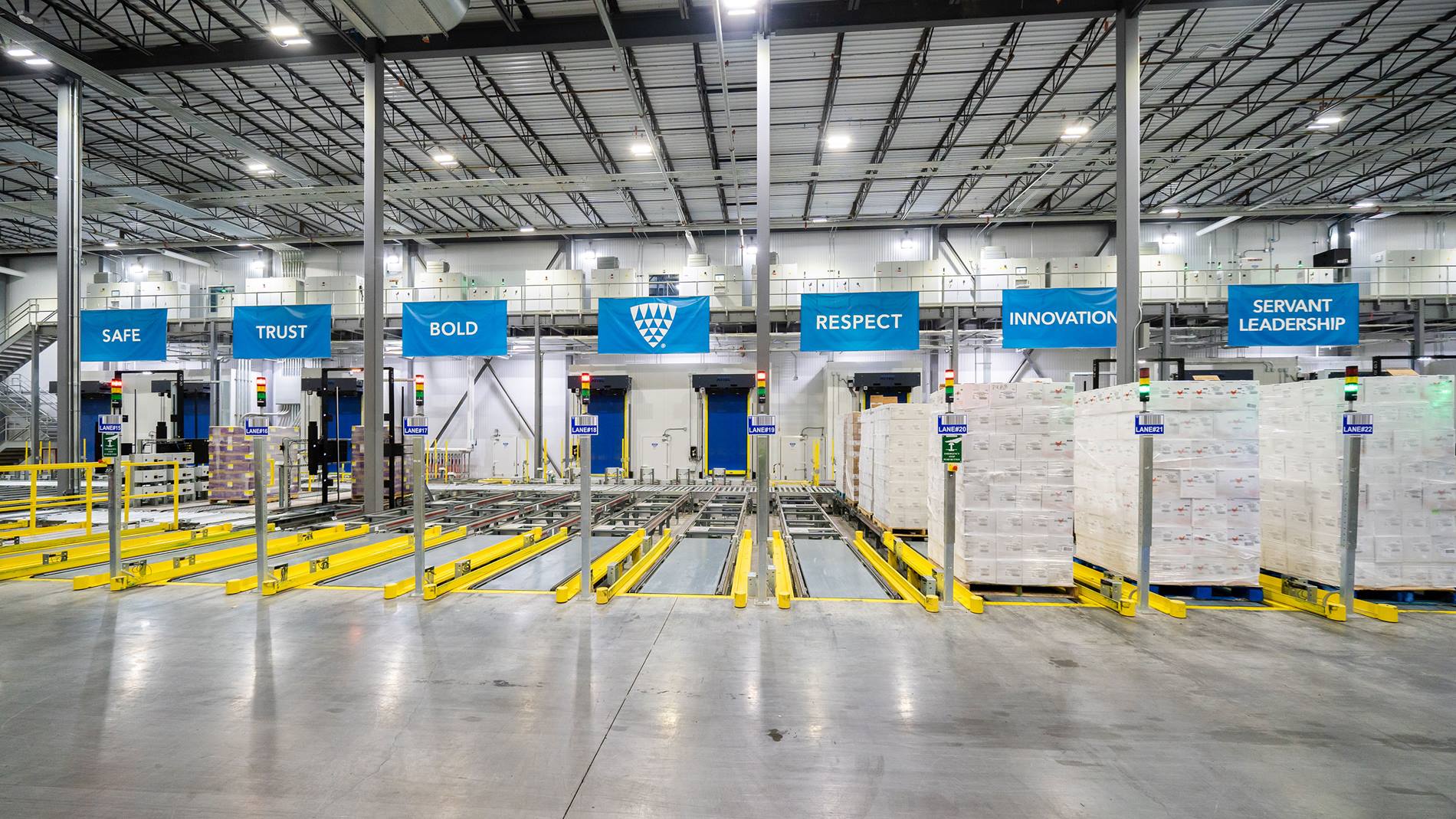

The PowerStore system at Sunnyvale is the largest ever deployed in a cold storage facility. It includes three modules stacked vertically to leverage the full height of the facility with nine aisle and row cart pairings per module. The system is supported by a full conveyor loop with six inbound lanes and 27 outbound lanes.

Three vertical lifts support each module: one primary inbound, one primary outbound and one that can be flexed between inbound and outbound depending on requirements. Pallets are stored in rack channels up to 17 deep within a 0° F environment. The PowerStore system is tailored for the cold storage environment with low viscosity lubricants, heated controls and the use of capacitors rather than batteries in the shuttles.

Surpassing Expectations

The PowerStore system achieves a throughput of 367 pallets an hour, enabling Lineage to meet its customers’ requirements to maintain smaller inventories. The system also enables turn times of just nine minutes from truckload order to all pallets ready for loading.

Our results have been very good. From the time we put in a truckload order to the time all the pallets arrive in the ready lane is just nine minutes—faster than the 12 minutes we had in our business case. We expect that to drop to six minutes as we gain more experience.