“Proximity, security and great commitment”

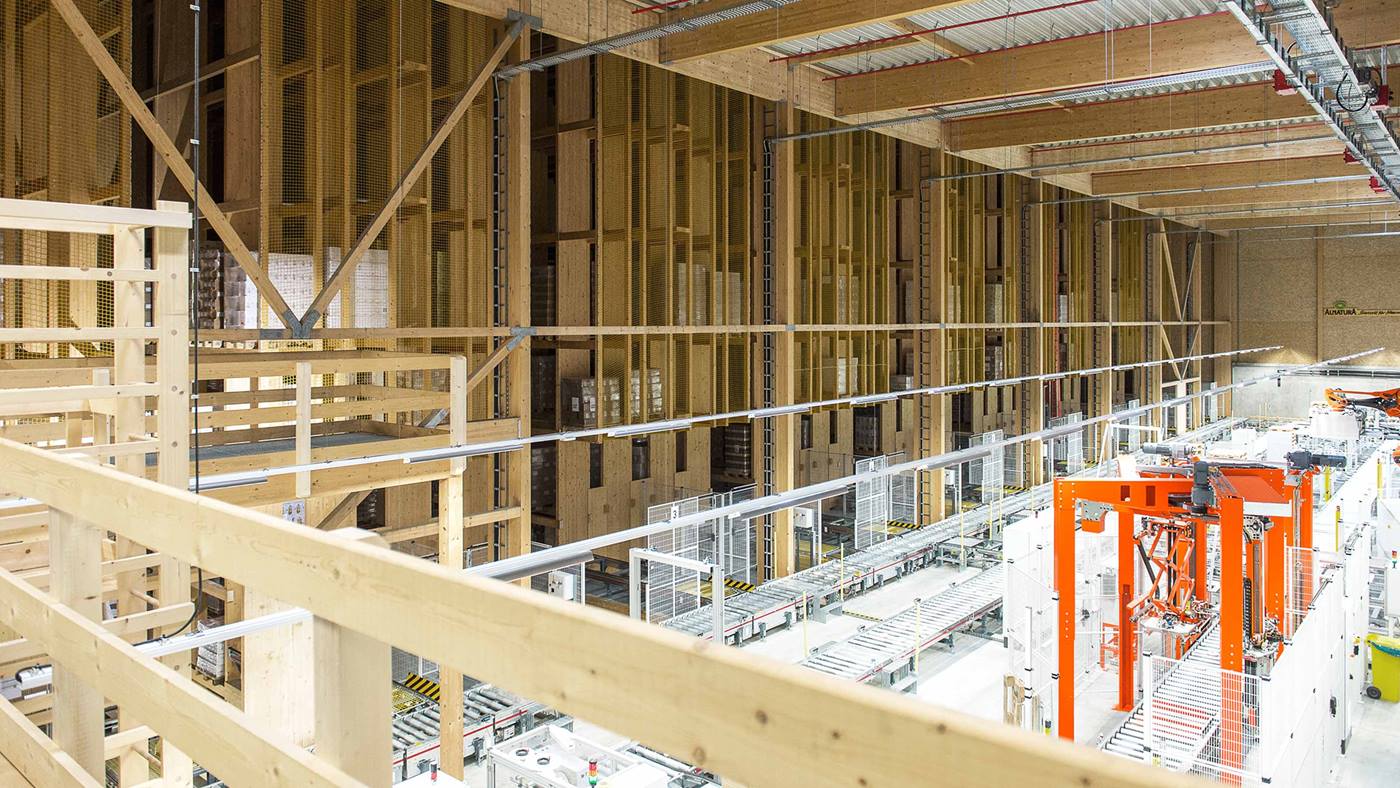

The automation facility – an automated high-bay warehouse for pallets and a ProMove conveyor solution that automatically transports the coffee from production to the warehouse – is dimensioned for 9,000 pallets and three pallet cranes. Initially, 6,000 pallet locations and two Vectura cranes are being built and installed, managed and controlled by Swisslog’s SynQ WMS software.

“This solution means that we can produce coffee in shifts without having staff in the warehouse. We also save a lot of space compared to, for instance, if we had built a manual pallet warehouse,” explains Peter.

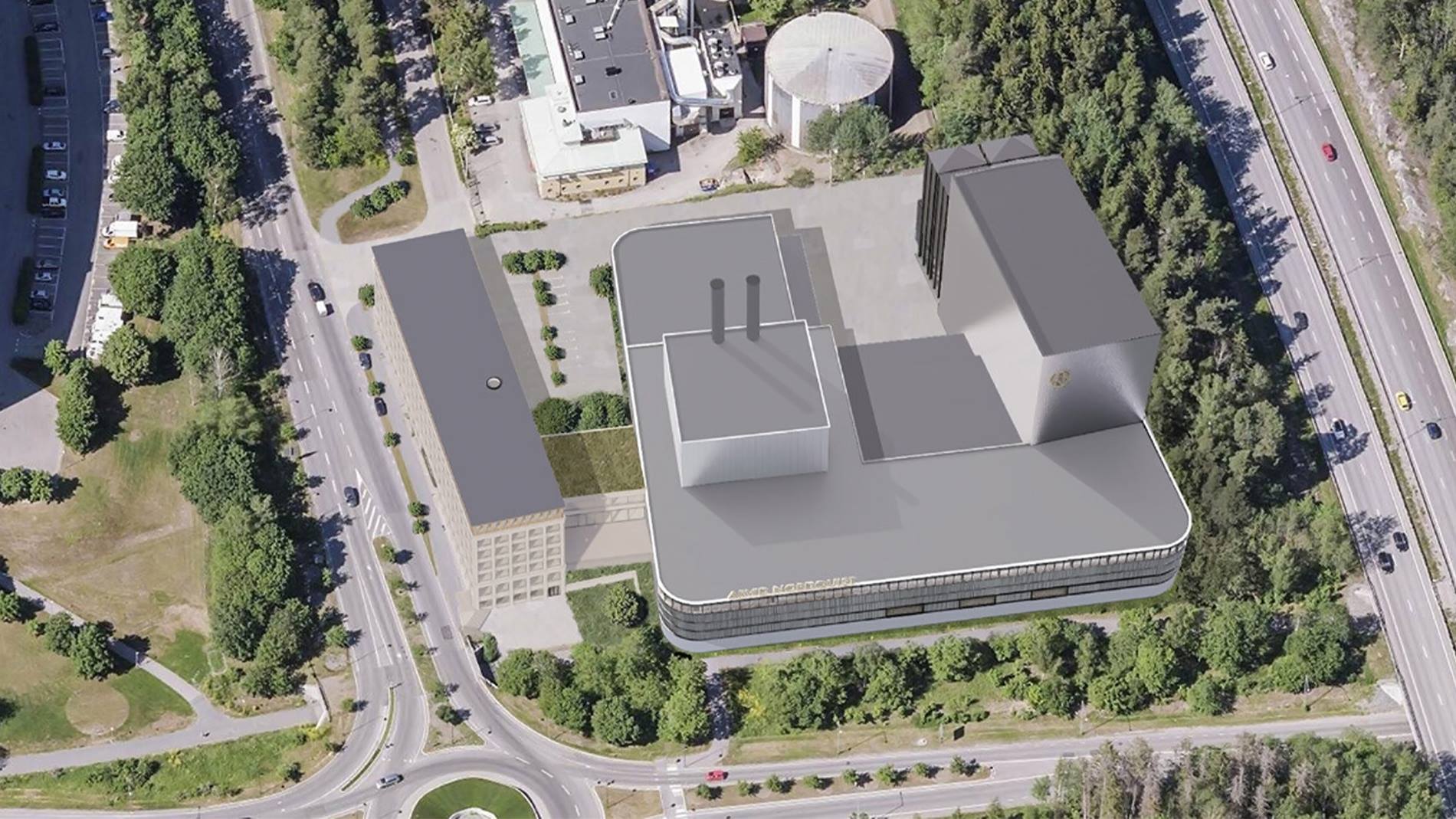

One year ago, a letter of intent was signed between Arvid Nordquist and Swisslog, which involved Swisslog developing a purely conceptual automation solution. Swisslog was chosen as the solution supplier due to a combination of factors.

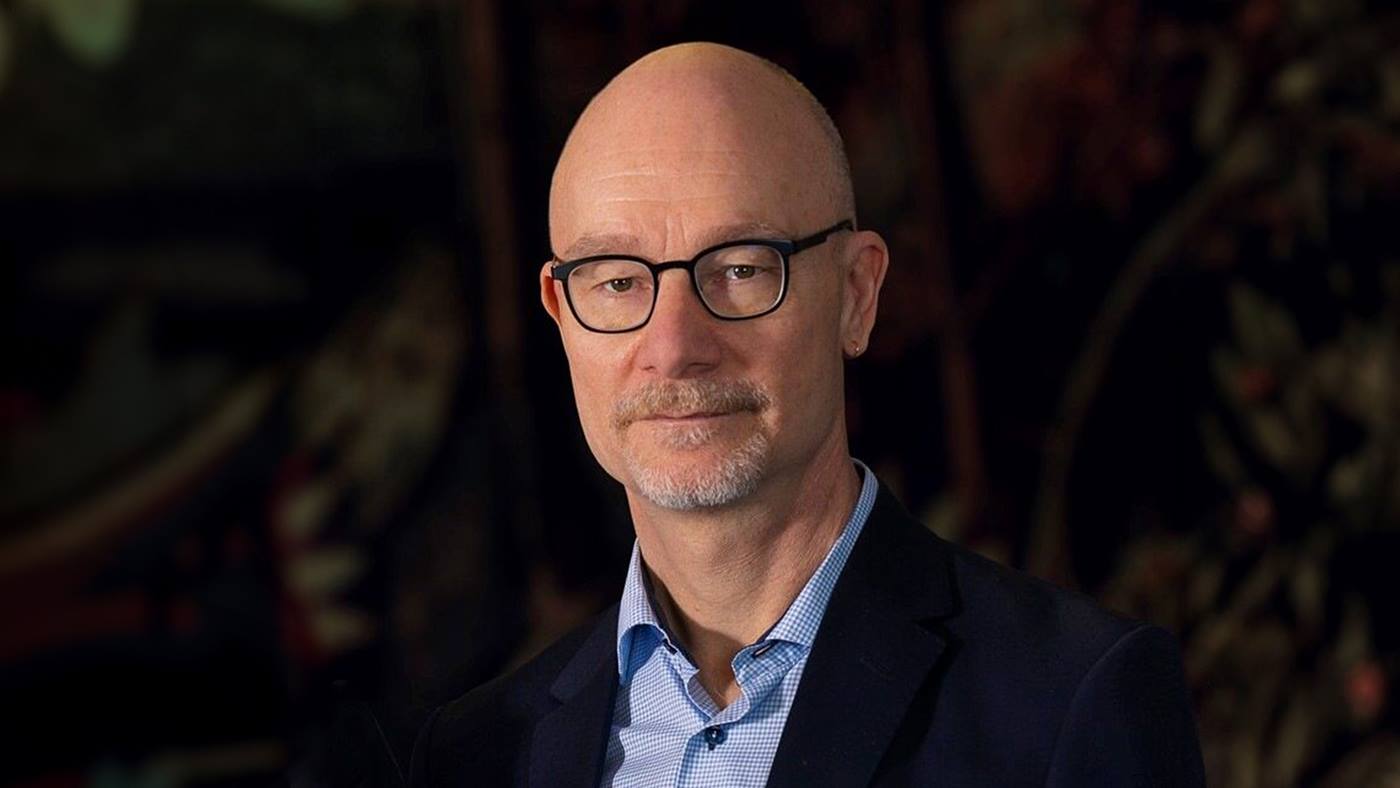

“Based on the solution developed, we held discussions with several automation companies. Apart from its competitive price, Swisslog’s market presence here in Sweden, their great commitment and their expertise were ultimately the reasons why we chose them. Swisslog simply felt the best and safest option,” says Peter.