New Guide Reviews How Case Picking and Palletizing is Changing and What It Means for Retail Distribution

At the same time, recruiting and retaining labor remains a persistent challenge at the distribution center and store level and case handling is one of the most physically demanding tasks in each location. Building pallets manually for retail store fulfillment is inefficient and results in pallets that increase workloads across the retail network as workers have to break down pallets and reorganize cases based on store layouts.

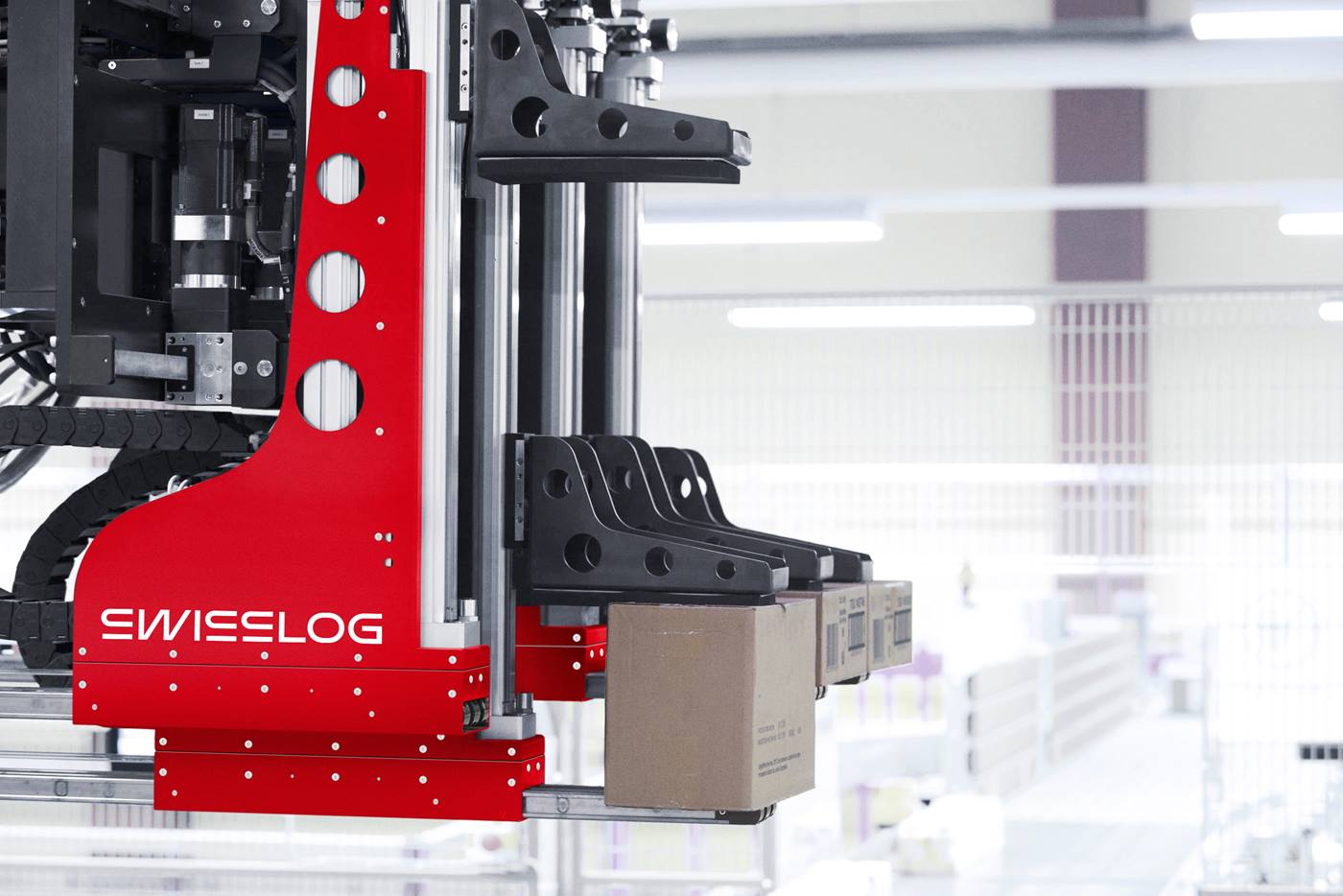

That has resulted in more retail distribution centers considering automating case picking and palletizing using the new generation of intelligent solutions now available. The new guide, Making the Case for Store- and Aisle-Friendly Fulfillment, is a collaboration between Swisslog and Modern Materials Handling that takes a deeper dive into this trend and explores the capabilities and use cases for robotic case picking and palletizing. To access the new guide, visit our reference section here.

Warehouse automation introduces efficiencies that enable organizations to increase productivity, respond faster to orders, and increase storage density. However, securing the capital required to support these initiatives is a hurdle some organizations struggle to overcome. Part of the challenge may be that these organizations fail to fully consider the hidden costs of maintaining the status quo. From falling behind competitors to rising costs to unpredictable service levels, carefully considering the costs of inaction should always be considered as part of the business case for warehouse automation.