Ongoing success in the organic and natural food industry with logistics automation

Strategic advantage on the road to success

- Proven industry expertise with success stories in production and distribution logistics, retail order processing and online shopping dispatch.

- Energy-efficient, automatic pallet storage and reliable small-volume handling

- Software solutions along your entire supply chain

Alnatura, Germany: High-bay pallet warehouse and small-volume shuttle

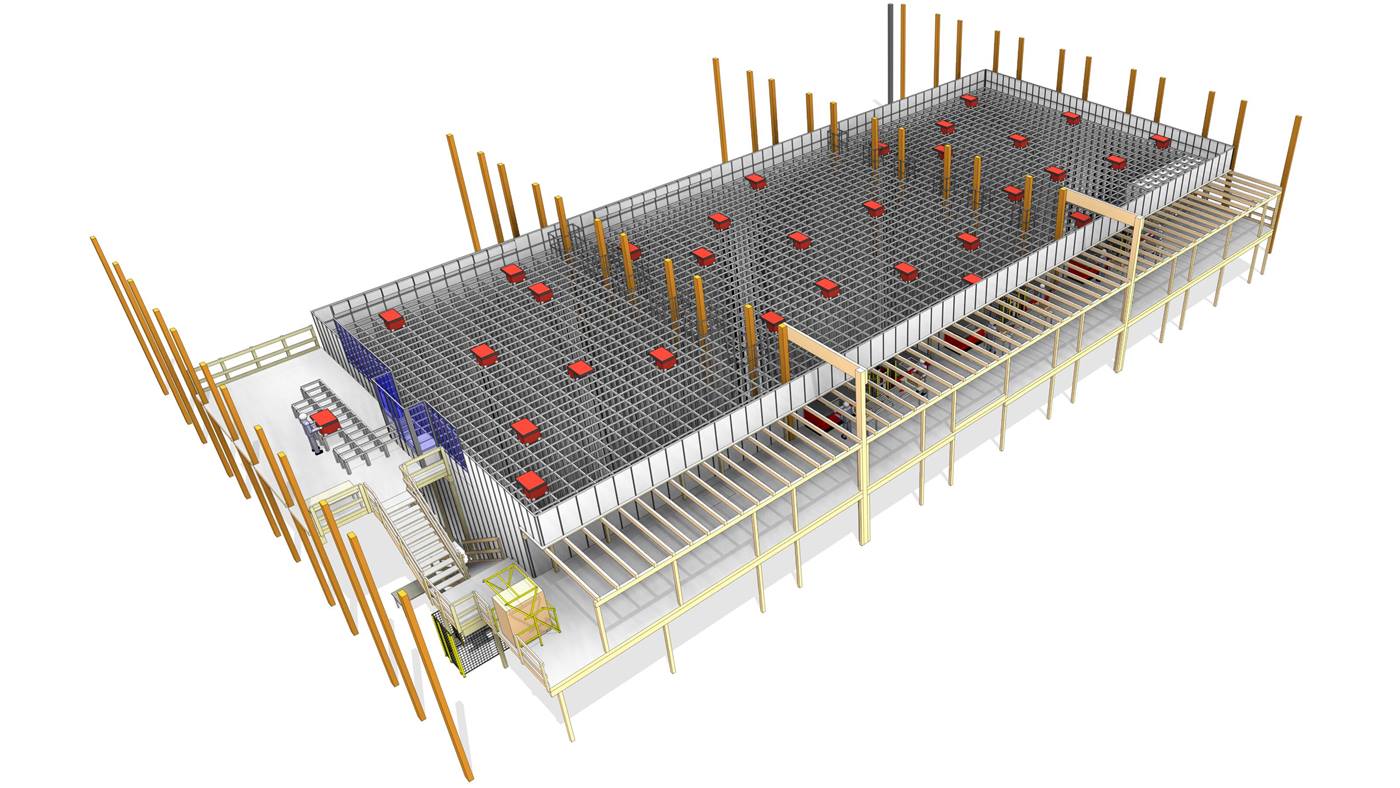

Alnatura's distribution center in Lorsch, which features particularly sustainable construction and operation, stands 17.5 meters high and is built entirely of wood. This new logistics center will reduce CO2 emissions – thanks to improved insulation and natural cooling, there is no need for artificial air conditioning.

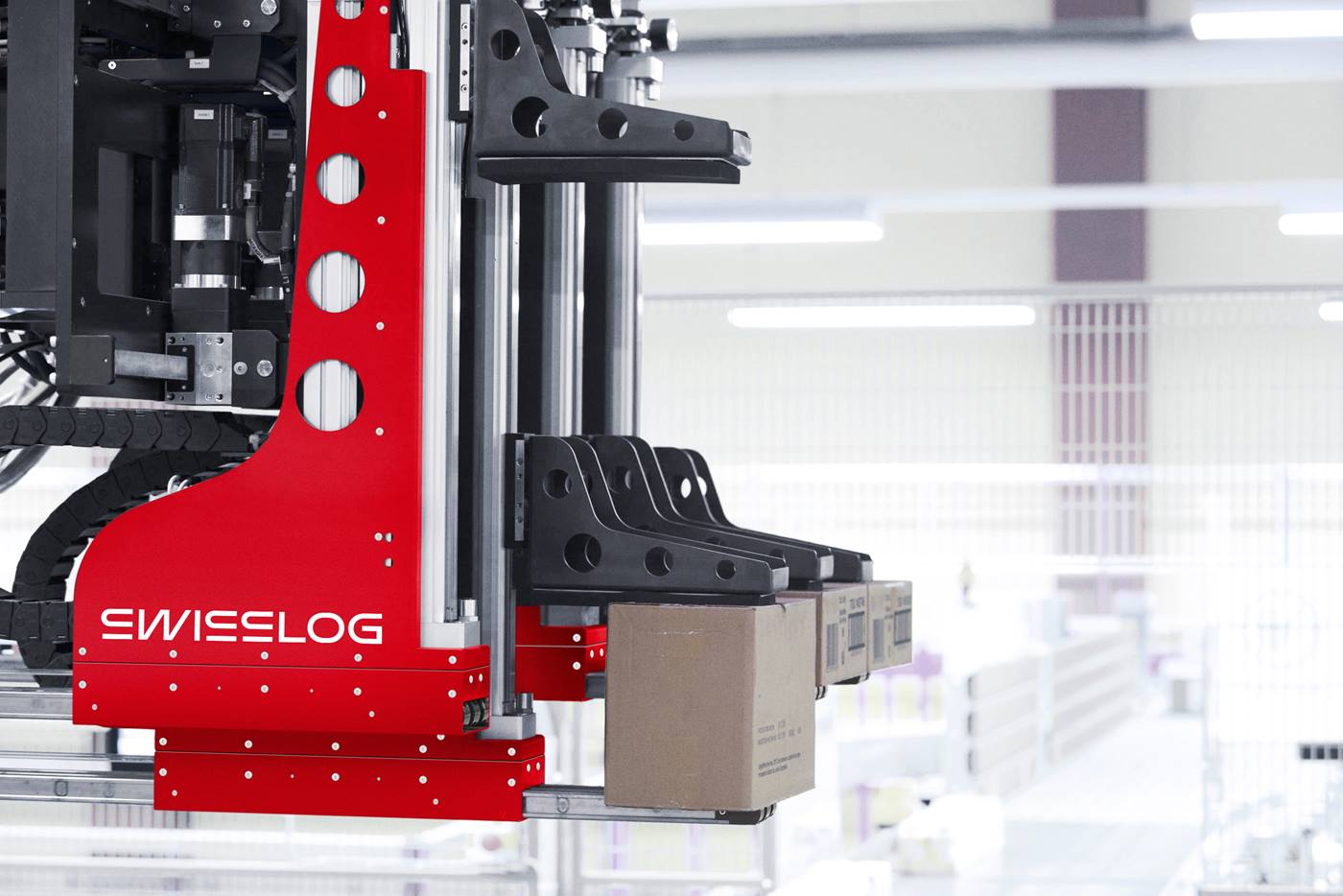

Swisslog's CycloneCarrier shuttle system has enabled Alnatura to centralize their warehouse logistics of small-volume organic items for the company’s expanding network of stores. This environmentally-friendly solution shortens transport routes and allows Alnatura to manage a larger range of articles.

Weiling, Germany and Bio Partner, Switzerland

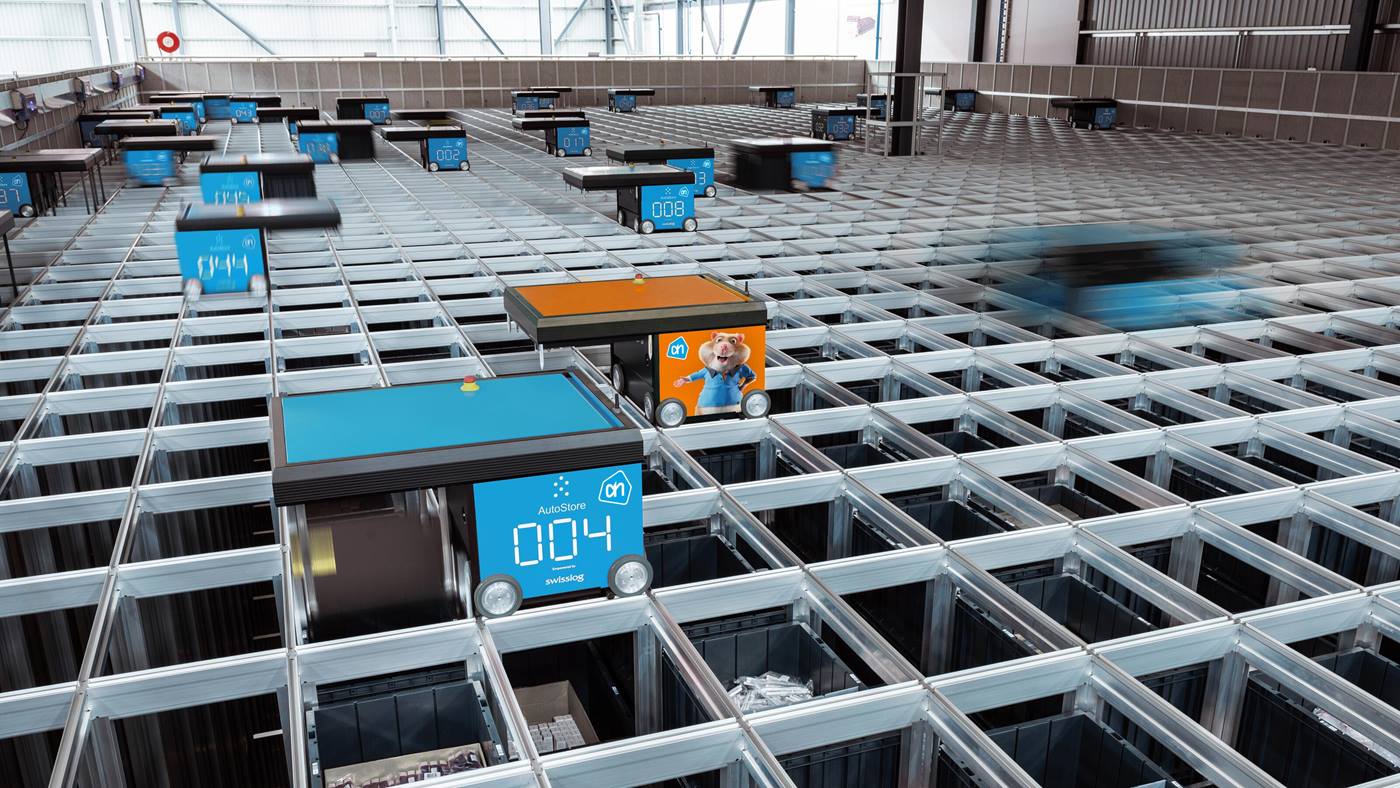

Weiling GmbH, headquartered in Coesfeld, is one of Germany's largest retail companies for organic food. Weiling has laid the foundation for additional growth with an automatic high-bay warehouse and an AutoStore for dry products.

Switzerland's leading organic retailer Bio Partner relies on a state-of-the-art AutoStore warehouse for more than 6,000 types of dry goods. This highly optimized solution transformed three formerly distinct warehouses into a single system.

Warehouse automation introduces efficiencies that enable organizations to increase productivity, respond faster to orders, and increase storage density. However, securing the capital required to support these initiatives is a hurdle some organizations struggle to overcome. Part of the challenge may be that these organizations fail to fully consider the hidden costs of maintaining the status quo. From falling behind competitors to rising costs to unpredictable service levels, carefully considering the costs of inaction should always be considered as part of the business case for warehouse automation.