ASKO, Norway: State-of-the-art distribution center enhances competitiveness, efficiency and profitability

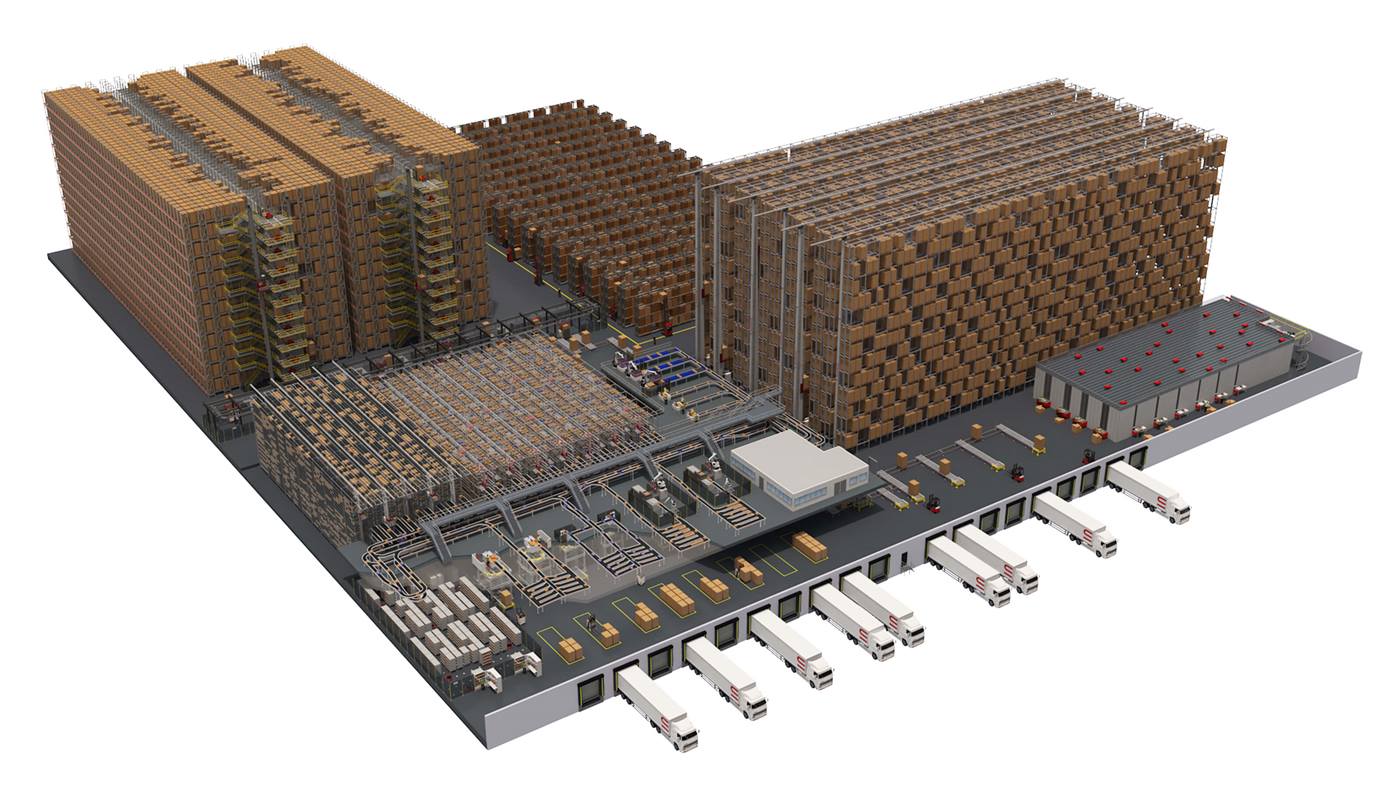

ASKO is Norway‘s largest wholesaler and distributor of groceries and part of NorgesGruppen, the country‘s marketleading grocery and convenience store chain with more than 1,900 stores. ASKO‘s mission is to ensure an efficient flow of groceries to all the stores, and to 1,200 kiosks and 12,500 hotels, restaurants, institutional households and cafes. Every week, up to half a million articles are transported through 22 picking stations at the distribution center.

Warehouse cost savings of more than 20 percent

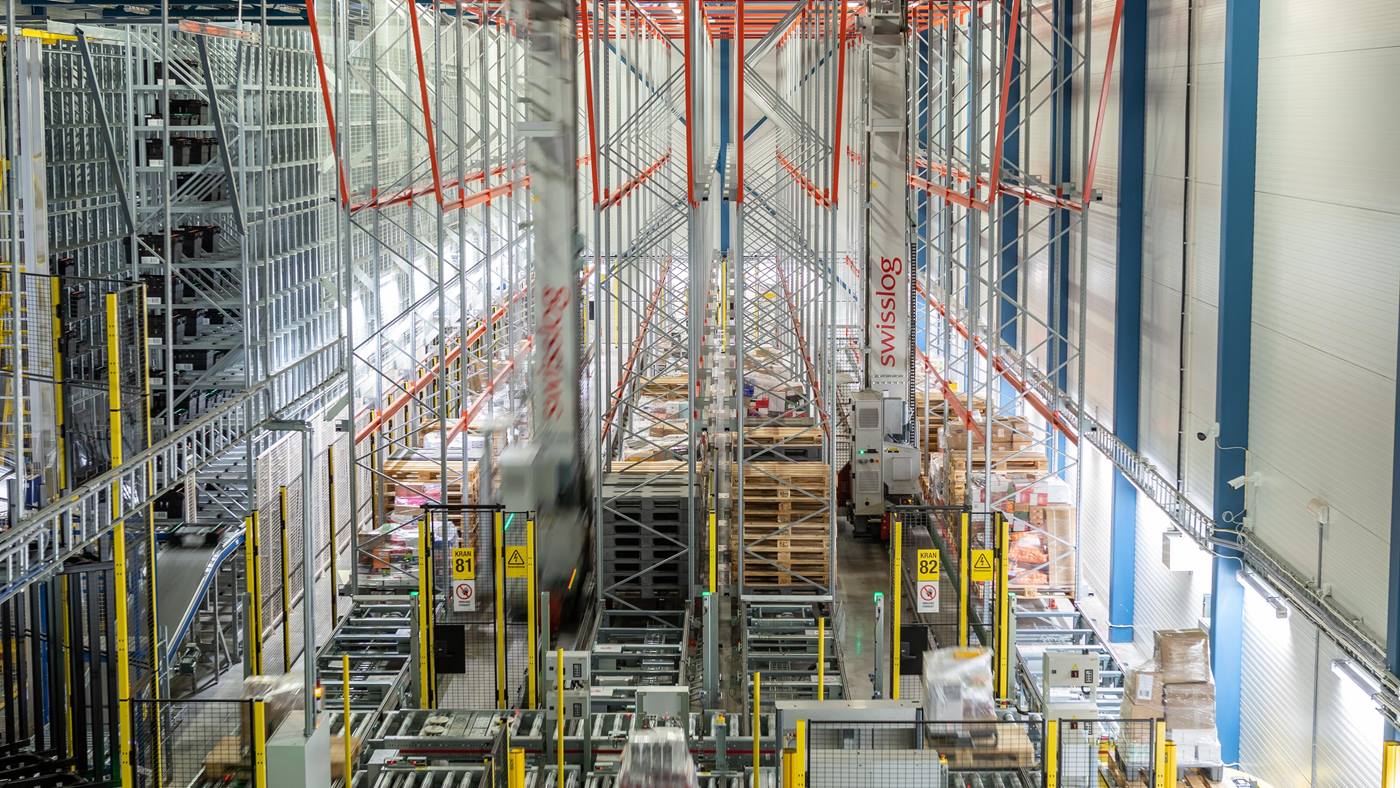

In five years of working in co-operation with Swisslog, ASKO has doubled its SKU range and become four times as efficient as it was before automation.

Every week, up to half a million articles are transported through 22 picking stations at the distribution center.

Continuous improvement

The partnership between ASKO and Swisslog is focused on continuous improvement and future development. The Swisslog team of 17 on-site technicians provides preventative and corrective maintenance.

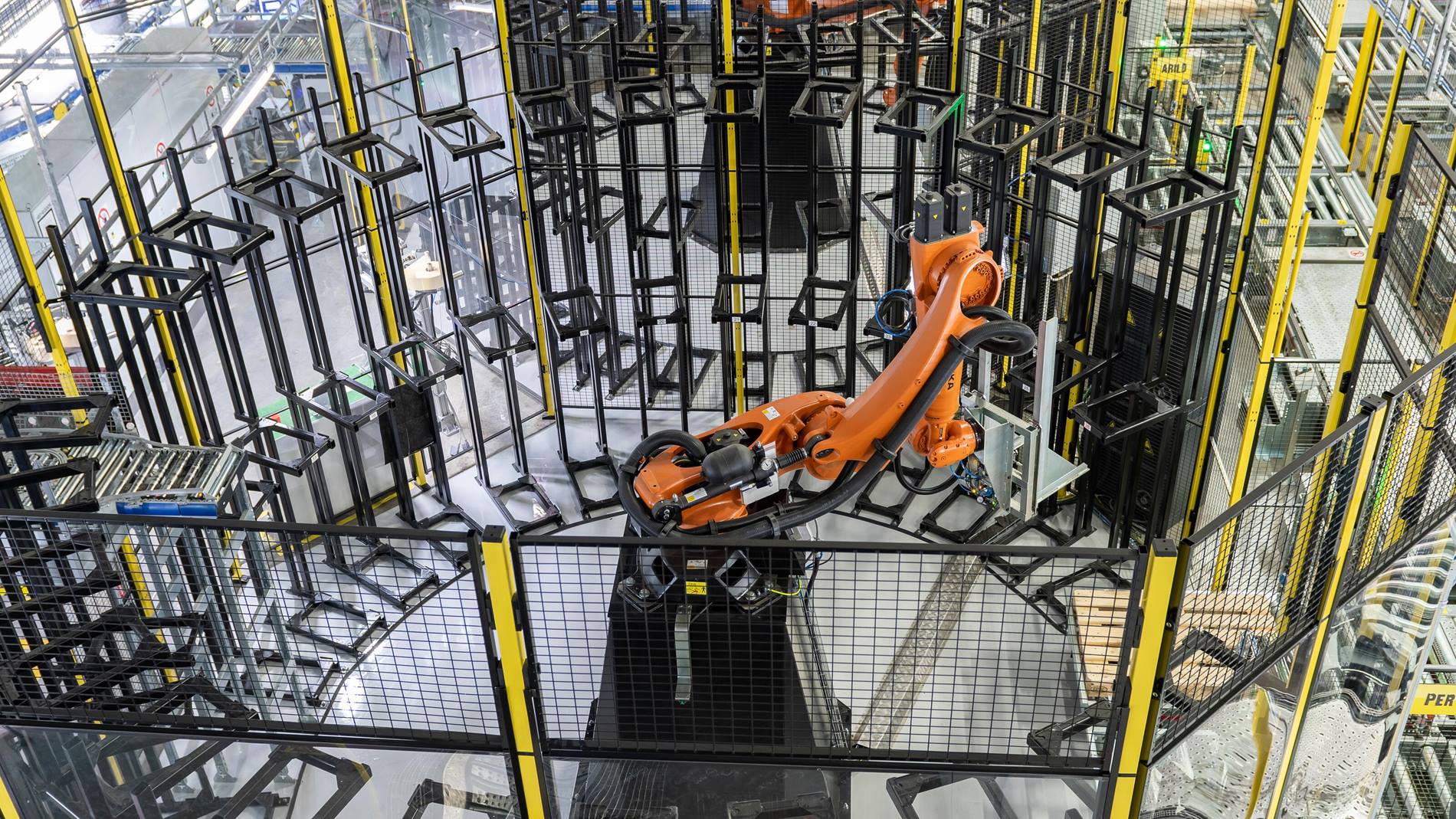

In recent years the facility has been further modernized with three decanting robots that have been installed to fully automate the decanting process for a part of the articles and thereby improving the throughput in the warehouse. Two highly efficient pick stations for smaller orders have been added. In addition, the consolidation has been fully automated with two Star Robot-applications and a pallet storage with two cranes. The robotization has improved the efficiency in the consolidation process significantly.

We now rely on the most, efficient and intelligent intralogistics solution when handling our 13,000 different products, with a five-hour response time limit, and an average of 4,000 orders per day. This is why we chose to automate, and it´s why we chose this particular solution from Swisslog.