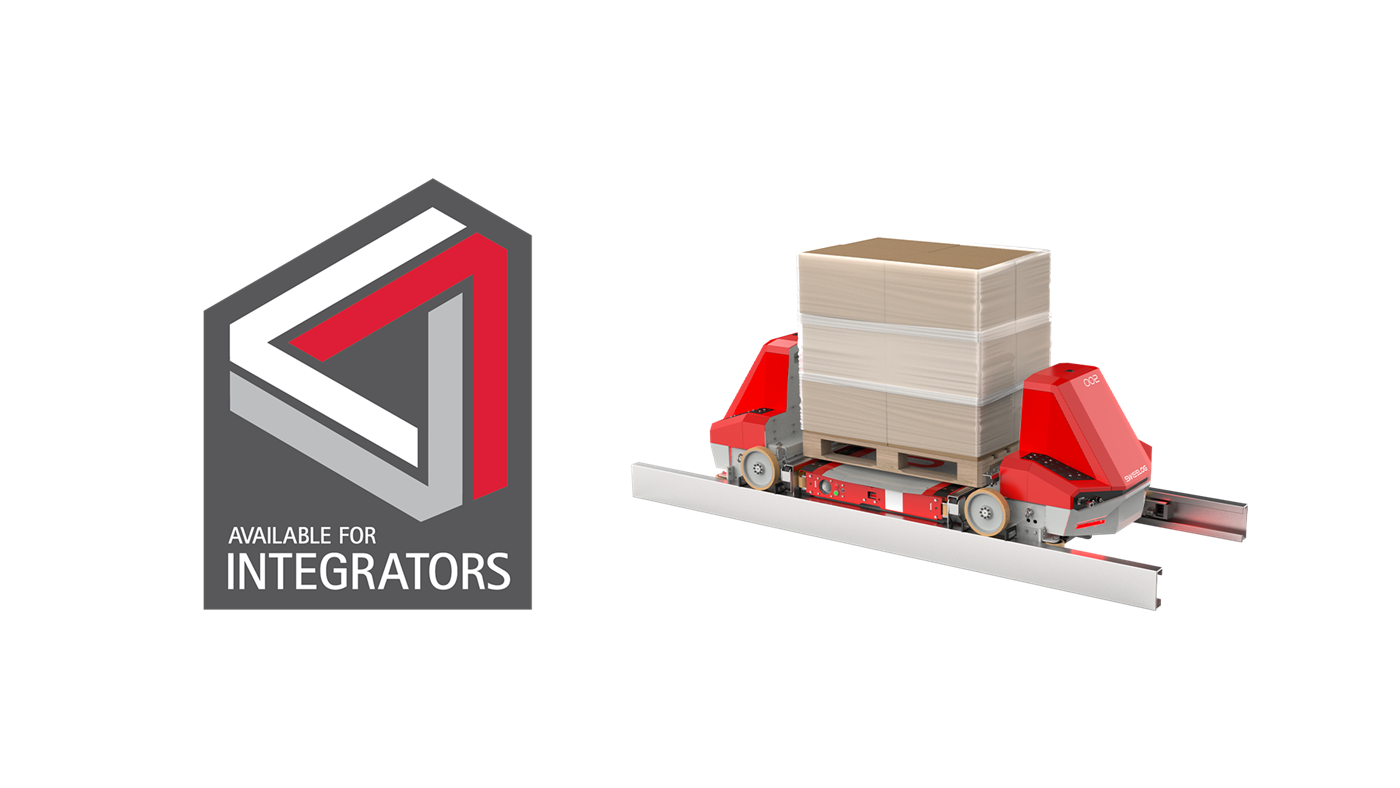

PowerStore: High density shuttle system for pallet warehousing

Do you want to maximize available space, remain flexible and increase throughput? PowerStore is the perfect high density pallet shuttle solution for warehouses with low ceilings, fewer unique products and high throughput requirements.

Compact storage with PowerStore shuttle system

The modularity of the PowerStore pallet shuttle system enables storage of up to 60% more pallets compared to manual systems. It can also be individually tailored for all shapes and sizes of warehouse buildings.

PowerStore pallet storage systems can be used in a wide range of environments, from -30°C in frozen food storage to 50°C. It can be used in buildings with unusual shapes. The modular design of the PowerStore system opens up completely new possibilities for automation in existing warehouses.

PowerStore is ideal for manufacturing businesses, especially those in the fast moving consumer goods and food and beverage industries.

What makes Swisslog’s PowerStore unique?

- Swisslog has invested more than 50 years of global experience to optimize a system with extremely high throughput and the utmost in reliability.

- We offer systems that feature highly accurate laser positioning, ensuring optimal positioning 100% of the time.

- PowerStore control software is fully integrated in Swisslog’s SynQ suite of warehouse management software and designed to work seamlessly with customers’ WMS and host systems.

- Low-height carriers save storage space while still enabling industry-leading lift heights. This allows for normal pallet deflections and minimizes the need for troubleshooting within the rack.

Imagine if you could reduce space by up to 60%? That is exactly what Pepsi did!

We looked for solutions to increase the density of our current warehouse space.

Read more about Pepsi in our customer case studies.